Product Details

| Specification | Details |

|---|---|

| Place of Origin | China |

| Brand Name | ASTON or OEM |

| Certification | SGS, CE, ROHS, ISO9001 |

| Coaxial Cable Daily Output | 200KM |

| Minimum Order Quantity | 50km |

Common Product Specifications

| Parameter | Value |

|---|---|

| Conductor | Copper-clad aluminum |

| Color | Black |

| Conductor Size | 1.63mm, 14AWG |

| Jacket Material | PVC, PE |

| Characteristic Impedance | 75 Ohm |

Manufacturing Process

The manufacturing process of RG11 coaxial cable involves a meticulous selection of materials, including copper-clad aluminum versus copper wire, to achieve optimal conductivity and durability. Research indicates that the copper-clad aluminum technique allows for a balance in cost-effectiveness and performance. Studies in industry-related papers emphasize the importance of precise engineering in layering aluminum with copper to harness the beneficial properties of both metals, particularly in maintaining electrical integrity and resisting environmental stressors. The process incorporates advanced machinery for insulation, sheath production, and quality testing to ensure compliance with global standards.

Product Application Scenarios

RG11 coaxial cables are pivotal in scenarios requiring high-frequency signal transmission, such as CATV and HDTV systems. Authoritative studies highlight their use in both residential and commercial installations where the choice between copper-clad aluminum and copper wire by manufacturers significantly impacts reliability and efficiency. These cables effectively handle the demands of broadcasting, data transmission, and telecommunication infrastructures, providing enhanced performance over extended cable runs due to their superior electrical properties.

Product After-Sales Service

Our commitment to customer satisfaction extends beyond the point of sale. Aston Cable provides comprehensive after-sales support including technical assistance, product replacement for faults, and warranty services tailored to assure peace of mind regarding product performance and longevity.

Product Transportation

The transportation of RG11 coaxial cables is optimized for safety and efficiency. Each batch undergoes meticulous packaging, designed to prevent damage during logistics, with shipments facilitated through reliable carriers. Our dispatch protocols ensure timely delivery to your specified location, with tracking capabilities to monitor your order's progress.

Product Advantages

- High conductivity and low signal loss

- Cost-effective alternative to pure copper

- Durable construction for harsh environments

- Adaptable for various applications including audio and video

- Produced by reputable manufacturers with stringent quality controls

Product FAQ

- What is the primary advantage of copper-clad aluminum vs copper wire? Copper-clad aluminum provides a cost-effective solution for applications where weight saving is crucial without compromising on conductivity for certain uses.

- How does the durability of copper-clad aluminum compare to pure copper? While copper-clad aluminum can be more susceptible to mechanical damage, its copper layer offers significant protection, making it adequate for many environments.

- Why choose RG11 coaxial cable? RG11 is ideal for long-distance transmission and handling high-frequency signals, making it suitable for broadcast and telecommunications functions.

- Can RG11 coaxial cable be used for HDTV? Yes, it supports 3GHz frequency, making it compatible with HDTV, CATV, and TV antennas.

- What testing standards do your cables meet? Our RG11 coaxial cables are SGS, CE, ROHS, and ISO9001 certified, ensuring they meet international quality and safety standards.

- Is there a minimum order quantity? Yes, the minimum order quantity for RG11 coaxial cable is 50km.

- What is the delivery time for a bulk order? Delivery times vary based on location and order size, but we aim to fulfill orders promptly, with detailed tracking provided.

- How do manufacturers ensure the cable's quality? Manufacturers employ advanced testing equipment and processes to ensure each cable meets specific electrical performance criteria and durability standards.

- What is the nominal velocity of propagation for this cable? The RG11 coaxial cable has an NVP of 84%, ensuring efficient signal transmission.

- How do copper-clad aluminum cables impact environmental sustainability? The use of aluminum reduces overall copper consumption, aligning with resource conservation goals while maintaining acceptable transmission performance.

Product Hot Topics

- The Evolution of Coaxial Cables: Copper Clad Aluminum vs Pure Copper

Coaxial cables have undergone significant changes with the introduction of copper-clad aluminum. This innovation challenges longstanding preferences for pure copper by offering a lighter and more cost-effective alternative. Industry experts and manufacturers often debate the balance between performance and cost, as copper-clad aluminum holds potential for various non-critical applications. As technology advances, the choice of materials continues to evolve to meet consumer demands and environmental considerations, reshaping the landscape of cable manufacturing.

- Understanding Electrical Conductivity: Manufacturers Weigh In on Copper Clad Aluminum vs Copper Wire

The debate between copper-clad aluminum and pure copper wire centers around electrical conductivity and application efficiency. Manufacturers emphasize that while pure copper boasts higher conductivity, copper-clad aluminum offers satisfactory performance where weight and cost are constraints. In coaxial cables, the copper layer plays a crucial role in maintaining signal integrity, making these cables suitable for a broad range of applications. Discussions among industry leaders highlight the importance of choosing the right material based on specific project needs and budget constraints.

- How Manufacturers Influence Quality in Coaxial Cables

The quality of coaxial cables, such as those using copper-clad aluminum versus copper wire, largely depends on manufacturing precision. Manufacturers prioritize meticulous processes, from material selection to rigorous testing, to ensure performance standards are met. This commitment to quality impacts signal transmission efficiency and the cable's longevity in varied environments. Experts suggest that understanding the manufacturer's capabilities and quality assurances is key when selecting cables for critical installs.

- The Role of Manufacturers in the Cost-Effectiveness of Copper Clad Aluminum

Manufacturers play a pivotal role in determining the cost-effectiveness of copper-clad aluminum coaxial cables. By leveraging advanced production techniques and economies of scale, they deliver products that offer substantial savings without significantly compromising on performance compared to pure copper. This makes copper-clad aluminum a preferred option in markets where budget constraints outweigh the necessity for maximum conductivity, impacting industries from telecommunications to consumer electronics.

- Environmental Impact: Copper Clad Aluminum vs Copper Wire

The transition from pure copper to copper-clad aluminum by manufacturers reflects broader environmental sustainability trends. The reduced copper content in these cables aligns with efforts to preserve natural resources and minimize ecological footprints. While debates continue regarding performance trade-offs, the environmental advantages present a compelling case for copper-clad aluminum, particularly in applications where top-tier conductivity is not imperative. This shift is reshaping perceptions around cable manufacturing and environmental responsibility.

- Innovation in Coaxial Cable Design: The Role of Copper Clad Aluminum vs Copper Wire

Innovations in coaxial cable design have been significantly impacted by the introduction of copper-clad aluminum. This trend illustrates manufacturers' response to evolving market demands for lighter, cost-efficient solutions without drastically reducing performance standards. Copper-clad aluminum's application in coaxial cables is a testament to the industry's ability to innovate while maintaining reliable signal transmission capacities, offering consumers more choices tailored to specific technical and financial requirements.

- Performance Metrics: Comparing Copper Clad Aluminum vs Copper Wire Coaxial Cables

Performance metrics of coaxial cables using copper-clad aluminum and pure copper are often compared to gauge suitability for different applications. Manufacturers emphasize that while copper provides superior conductivity, copper-clad aluminum achieves adequate performance levels where extreme efficiency is not critical. Understanding these metrics is essential for buyers looking to balance technical needs with cost savings, particularly in projects with extensive cabling requirements.

- The Future of Coaxial Cables: Manufacturers' Perspectives on Material Choices

The future of coaxial cables, influenced by material choices like copper-clad aluminum versus pure copper, is a topic of keen interest among manufacturers. As technology advances, the need for versatile yet cost-effective materials grows. Manufacturers predict a continued evolution in cable design, driven by consumer demand for improved performance and sustainability. This dynamic landscape promises ongoing innovations that will redefine standards across various technological applications.

- Impact of Copper Clad Aluminum on Coaxial Cable Durability

The durability of coaxial cables using copper-clad aluminum is a critical consideration for manufacturers and consumers alike. Despite being more prone to mechanical damage compared to pure copper, advancements in manufacturing processes have enhanced its resilience, making it suitable for many environments. This durability, coupled with cost benefits, positions copper-clad aluminum as a viable alternative for a range of applications, prompting manufacturers to refine techniques to further enhance its reliability.

- Consumer Insights: Choosing Between Copper Clad Aluminum vs Copper Wire

For consumers, choosing between copper-clad aluminum and pure copper wire in coaxial cables involves carefully weighing performance needs against budget constraints. Manufacturers provide extensive information highlighting the strengths and limitations of each material. While copper ensures optimal conductivity, copper-clad aluminum offers an economical option for projects where weight and cost are primary considerations. Consumer insights reveal a growing acceptance of copper-clad aluminum, as long as it aligns with project specifications and performance expectations.

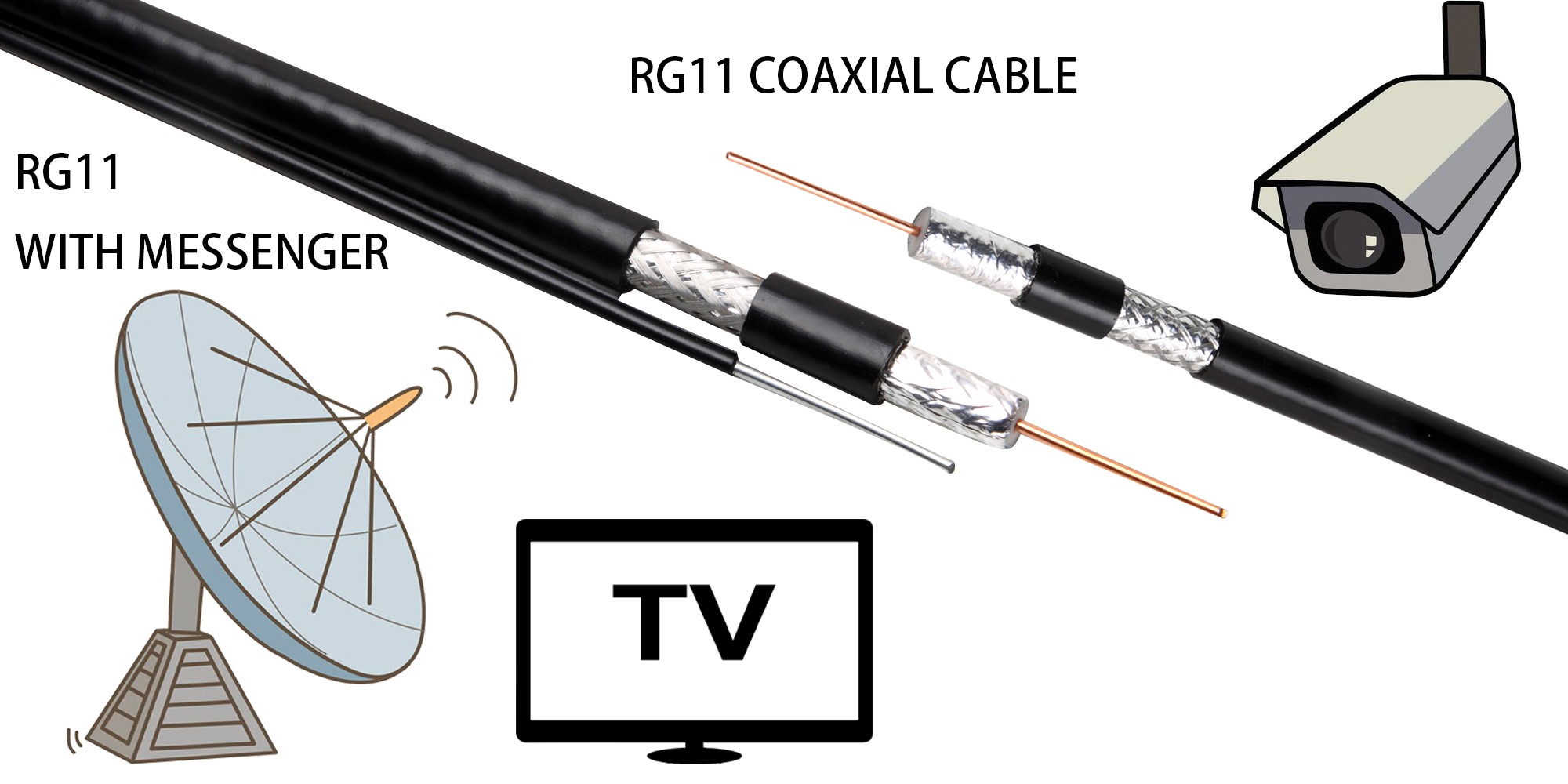

Image Description