Product Main Parameters

| Parameter | Specification |

|---|---|

| Origin | China |

| Brand Name | ASTON or OEM |

| Certification | SGS, CE, ROHS, ISO9001 |

| Daily Output | 200KM |

| Minimum Order Quantity | 30km |

| Price | Negotiable |

| Packaging | Normal export packaging |

| Supply Ability | 25000KM/Per year |

| Delivery Port | Ningbo |

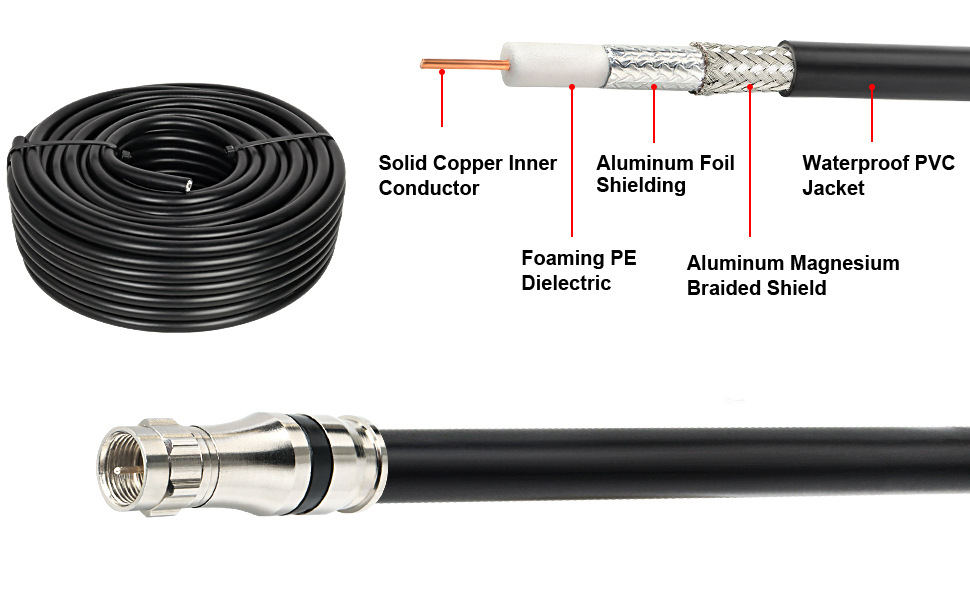

Common Product Specifications

| Specification | Details |

|---|---|

| Jackets | PVC, PE for outdoor |

| Color | Black |

| Conductor | 1.63mm 14AWG |

| Usage | Radio guide cable |

| Logo | OEM |

| Industrial Use | Data transmission cable |

| Cable Length | 304.8 m | 1000 ft |

| Diameter Over Center Conductor | 0.0641 in per 1 strand |

| Diameter Over Dielectric | 7.112 mm | 0.28 in |

| Diameter Over Jacket Tolerance | ±0.008 in |

| Diameter Over Jacket, Nominal | 9.169 mm | 0.361 in |

| Diameter Over Shield (Braid) | 8.179 mm | 0.322 in |

| Jacket Thickness | 0.508 mm | 0.02 in |

| Jacket Thickness, Minimum Spot | 0.406 mm | 0.016 in |

| Center Conductor Gauge | 14 AWG |

| Inner Shield (Braid) Gauge | 34 AWG |

| Capacitance | 52.493 pF/m | 16 pF/ft |

| Characteristic Impedance | 75 ohm |

| Dielectric Strength, Conductor to Shield | 4000 Vdc |

| Conductor dc Resistance | 36.089 ohms/km | 11 ohms/kft |

| Nominal Velocity of Propagation (NVP) | 84 % |

| Jacket Spark Test Voltage | 5000 Vac |

| Structural Return Loss Test Method | 100% Swept Tested |

| Structural Return Loss | 15 dB @ 1000–3000 MHz | 20 dB @ 5–1000 MHz |

Product Manufacturing Process

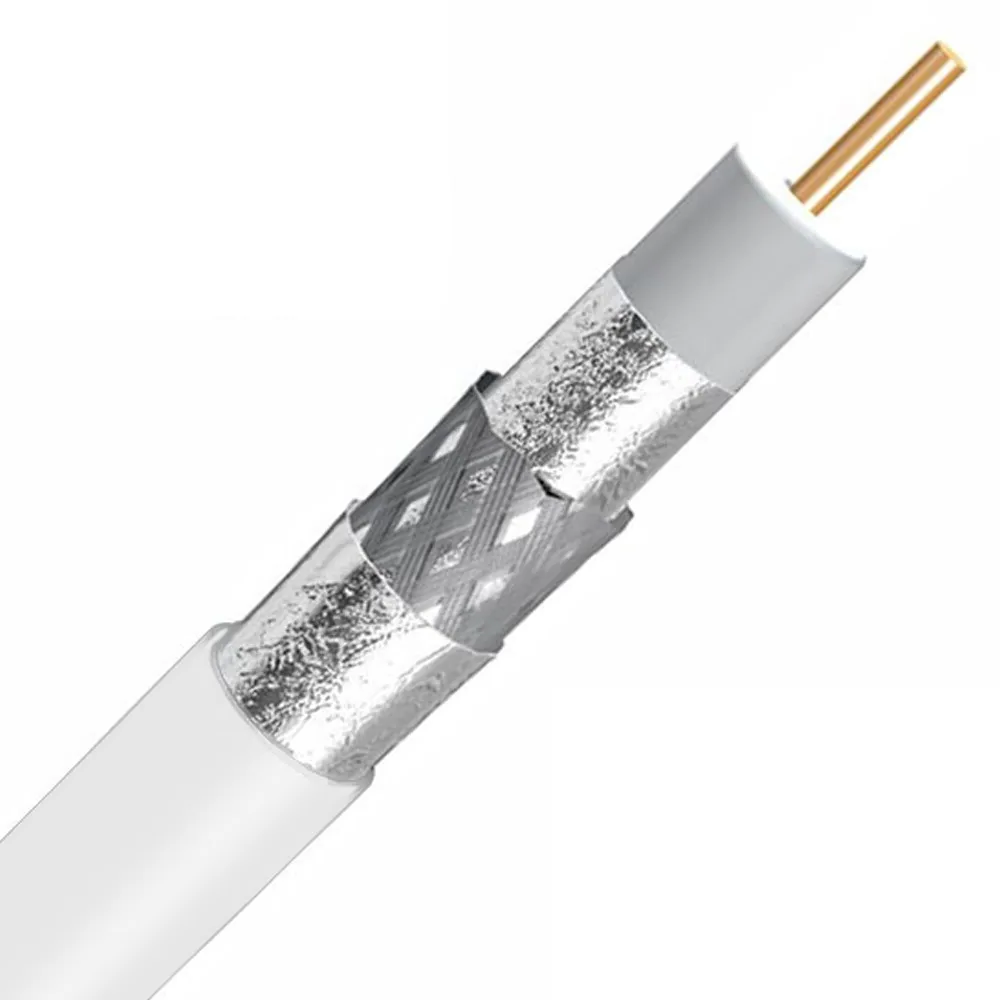

The manufacturing process of copper clad aluminium wire, according to authoritative sources, involves a meticulous metallurgical bonding between the aluminium core and the copper cladding. The copper layer typically comprises about 10% to 15% of the total cross-sectional area, achieved through processes such as extrusion or co-drawing. This ensures a robust electrical bond, preventing the copper from separating from the aluminium core—resulting in a stable, high-performing conductor. The careful control of the bonding process is essential for maintaining the consistent electrical properties and ensuring the wire's longevity and performance.

Product Application Scenarios

Copper clad aluminium wire is particularly advantageous in scenarios where moderate conductivity and reduced weight combine with cost-efficiency to meet industry needs. Authoritative papers highlight its use in telecommunications—specifically in coaxial cables and Ethernet cables—leveraging the skin effect for effective high-frequency signal transmission. Its lightweight makes it a preferred choice in the aerospace and automotive industries, where it contributes to fuel efficiency and performance. Although less common, copper clad aluminium wire can be used in residential wiring, provided compliance with local building codes is met, which may restrict its use in favor of pure copper wire.

Product After-sales Service

We offer comprehensive after-sales service, ensuring customer satisfaction through timely assistance and support. Our dedicated team is ready to address any issues regarding the performance or quality of our RG11 coaxial cable products. We prioritize quick resolution of complaints, replacement of defective goods, and guidance on product usage. Additionally, we provide warranty coverage terms to safeguard your investment, backed by our confidence in the quality of our copper clad aluminium wire products.

Product Transportation

Our products are shipped using sturdy and reliable packaging to ensure safety and integrity during transit. We partner with reputable logistics providers to facilitate timely and efficient delivery. For bulk orders, we offer flexible shipping options, including sea freight and air freight, depending on the urgency and destination. Our team ensures that all export documentation and compliance requirements are met, providing a seamless delivery experience for our customers globally.

Product Advantages

- Cost Efficiency: Copper clad aluminium wire offers significant cost savings over pure copper while maintaining adequate conductivity for many applications.

- Weight Reduction: Its lightweight nature makes it ideal for industries like aerospace and automotive, where weight reduction is crucial.

- Conductivity: The copper cladding ensures minimal loss of conductivity, ideal for high-frequency applications.

- Corrosion Resistance: The copper layer provides a protective barrier against environmental corrosion, increasing wire longevity.

- Versatility: Suitable for telecommunications, networking, and more, where moderate conductivity suffices.

Product FAQ

- What is the main advantage of using copper clad aluminium wire?

Suppliers often recommend copper clad aluminium wire due to its cost-effectiveness and lightweight characteristics, making it suitable for applications where reducing weight and expense is critical without major compromises on conductivity.

- Are there any limitations to using copper clad aluminium wire?

Suppliers acknowledge limitations such as lower overall conductivity compared to pure copper and reduced mechanical flexibility, which may impact its application in certain settings or for long-distance electrical transmission.

- Can copper clad aluminium wire be used in residential electrical systems?

Its use in residential wiring often depends on local building codes; suppliers advise checking compliance as some regions restrict or prefer pure copper due to performance considerations.

- How does the skin effect benefit copper clad aluminium wire?

Suppliers note that the skin effect concentrates current flow on the wire's outer layer, enhancing copper clad aluminium wire efficiency in high-frequency uses, despite an aluminium core.

- What industries benefit most from copper clad aluminium wire?

Suppliers indicate that telecommunications, automotive, and aerospace industries benefit considerably due to the wire's light weight, cost-efficiency, and sufficient conductivity.

- How does the bonding process of copper clad aluminium wire affect its performance?

Suppliers highlight that the metallurgical bonding ensures copper does not peel from the aluminium core, providing reliable performance essential for various applications.

- Are there any environmental benefits to using copper clad aluminium wire?

Suppliers sometimes point out that, due to reduced weight and material usage, copper clad aluminium wire might contribute to lower transportation emissions and resource consumption.

- What is the typical copper layer percentage in copper clad aluminium wire?

Suppliers typically manufacture copper clad aluminium wire with a copper layer constituting around 10% to 15% of its cross-sectional area, tailored to specific applications.

- Does copper clad aluminium wire conform to international standards?

Suppliers ensure that copper clad aluminium wire adheres to various international standards, like RoHS and CE, emphasizing safety and compatibility in global markets.

- How do suppliers ensure the quality of copper clad aluminium wire?

Suppliers maintain rigorous quality control systems, from manufacturing to testing, to ensure that copper clad aluminium wire meets performance and safety standards.

Product Hot Topics

- The Role of Copper Clad Aluminium Wire in Telecom Infrastructure

In discussions with suppliers, copper clad aluminium wire emerges as a pivotal component in telecom infrastructure. Its cost-effectiveness and adequate conductivity under high-frequency conditions make it a preferred choice for network deployments. As telecom providers expand their reach, especially in challenging economic landscapes, these wires represent a balance between performance and expenditure, fostering connectivity growth while managing resource allocation strategically.

- Sustainable Practices in Copper Clad Aluminium Wire Production

With sustainability gaining traction, suppliers highlight the eco-friendly aspects of copper clad aluminium wire production. This involves optimizing resource use, reducing carbon footprints during manufacturing, and ensuring waste minimization. The wire's lightweight nature also contributes to environmental benefits by lowering transportation emissions, aligning with global efforts toward greener industrial practices while maintaining quality and performance.

- Comparative Analysis: Copper Clad Aluminium Wire vs. Pure Copper Wire

Suppliers often engage in detailed analyses comparing copper clad aluminium wire with traditional pure copper wire. While pure copper offers superior conductivity, the aluminium variant excels in cost and weight benefits. This analysis informs buyers on choosing materials best suited for particular applications, considering budget constraints and performance expectations, highlighting the strategic use of copper clad aluminium wire in appropriate settings.

- Copper Clad Aluminium Wire: Addressing Common Myths

Educational content from suppliers frequently addresses prevalent myths surrounding copper clad aluminium wire. These include misconceptions about its conductivity and durability. By highlighting its scientifically validated advantages, such as the skin effect's role in conductivity, suppliers clarify misunderstandings, enabling informed decision-making among consumers and industry professionals considering this versatile wire type.

- Future Innovations in Copper Clad Aluminium Wire Technology

Conversations with suppliers often touch on prospective innovations in copper clad aluminium wire technology. This includes advancements in metallurgical bonding techniques and enhanced cladding processes to improve wire performance further. Suppliers remain committed to research and development, paving the way for wires that meet emerging technological demands while continuing to offer cost-effective solutions in dynamic industrial applications.

- Evaluating Copper Clad Aluminium Wire in Auto Industry Applications

Suppliers highlight copper clad aluminium wire's role in the automotive industry, emphasizing weight reduction and cost considerations. As automakers strive for efficiency and sustainability, this wire offers benefits in electrical systems without significant compromises on performance. The automotive sector's shift towards lightweight materials marks copper clad aluminium wire as a key player in its evolution, balancing economic and functional needs.

- Copper Clad Aluminium Wire in Aerospace: Meeting Lightweight Demands

In aerospace applications, suppliers cite the importance of copper clad aluminium wire in meeting stringent lightweight demands. The wire's reduced mass contributes to fuel efficiency and cost savings, aligning with the industry's rigorous performance standards. Its adoption underscores the balance between maintaining aerospace integrity and optimizing for economic and environmental gains, crucial in today's competitive aviation market.

- Quality Assurance in Copper Clad Aluminium Wire: A Supplier’s Perspective

Suppliers emphasize rigorous quality assurance processes in copper clad aluminium wire production, ensuring product excellence and reliability. Consistent testing and industry compliance highlight commitment to high standards, addressing customer concerns regarding performance and safety. Suppliers' dedication to quality assurance underpins consumer confidence, solidifying copper clad aluminium wire's place in diverse applications across industries.

- Emerging Markets and Copper Clad Aluminium Wire Demand Trends

Suppliers observe increasing demand for copper clad aluminium wire in emerging markets, driven by infrastructural growth and cost constraints. The wire's affordability and adequate performance suit the expanding needs in telecommunications and construction, offering a viable solution where budgetary considerations are paramount. This trend underscores the wire’s significance in supporting development initiatives, contributing to economic progression globally.

- Regulatory Compliance for Copper Clad Aluminium Wire

Suppliers stress the importance of regulatory compliance in copper clad aluminium wire usage, navigating regional standards and building codes. Ensuring conformity with certifications like RoHS and CE assures safety and compatibility, fostering trust among stakeholders. Adhering to these regulations emphasizes the supplier's commitment to responsible manufacturing practices and aligns with global market expectations, facilitating seamless product integration and acceptance.

Image Description