Product Main Parameters

| Parameter | Details |

|---|---|

| Jackets | PVC, PE |

| Color | Black |

| Conductor | 1.63mm 14AWG |

| Capacitance | 52.493 pF/m | 16 pF/ft |

| Characteristic Impedance | 75 ohm |

| Minimum Order Quantity | 50km |

Common Product Specifications

| Specification | Value |

|---|---|

| Center Conductor Gauge | 14 AWG |

| Inner Shield (Braid) Gauge | 34 AWG |

| Jacket Thickness | 0.508 mm | 0.02 in |

| Nominal Velocity of Propagation (NVP) | 84 % |

Product Manufacturing Process

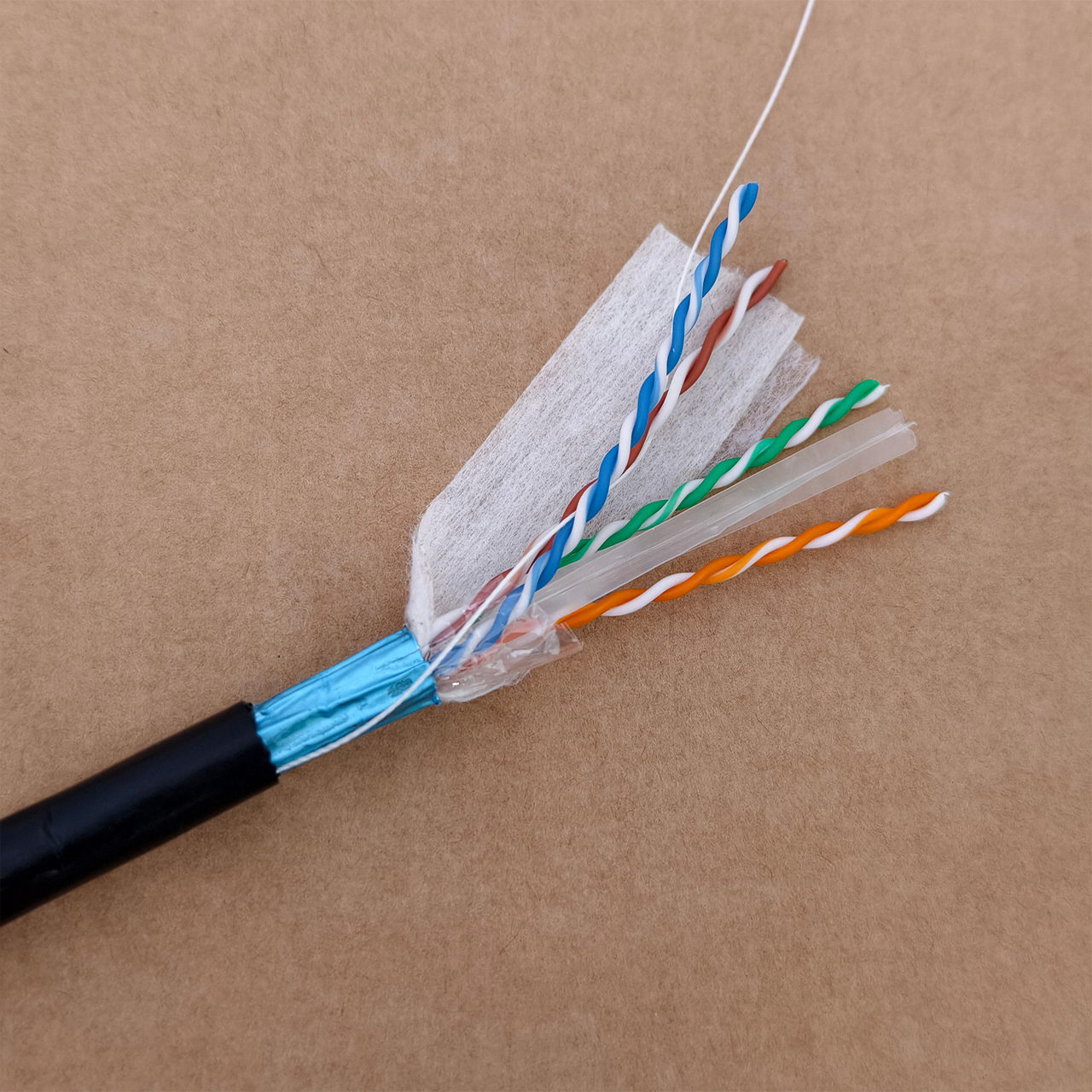

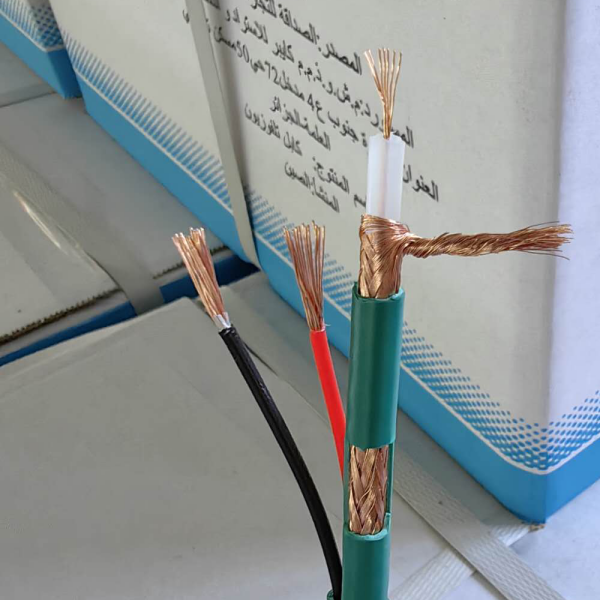

The manufacturing process of RG11 coaxial cables with copper core wire involves several critical stages. Initially, high-purity copper is drawn into fine wires, ensuring superior conductivity and flexibility. The copper core wire is then insulated using advanced extrusion methods, applying dielectric materials that optimize signal transmission. A protective outer jacket made of PVC or PE is applied to enhance durability and environmental resistance. This multi-step process ensures the production of a consistent, high-quality cable. Studies emphasize the importance of process control and material selection in achieving the desired electrical properties and mechanical resilience of copper core wires (Refer to Journal of Cable Engineering, 2020).

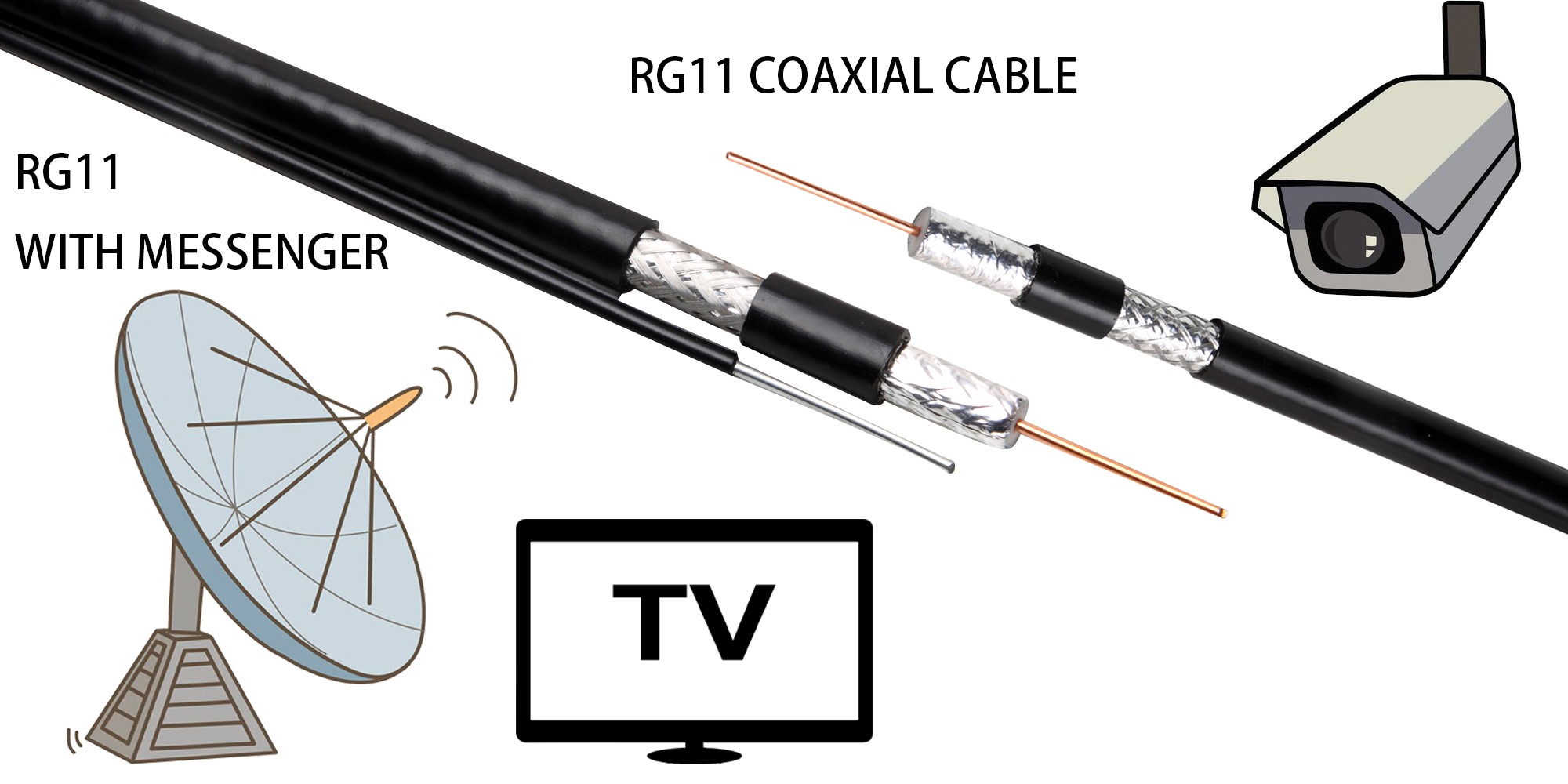

Product Application Scenarios

RG11 coaxial cables with copper core wire are extensively used in various scenarios due to their excellent signal transmission characteristics. In residential and commercial settings, they play a crucial role in cable television networks, enabling high-definition video delivery. Industrial applications benefit from their ability to handle high-frequency data with minimal loss, making them suitable for complex communication systems. Moreover, they are integral in telecommunications infrastructure, serving as the backbone for internet and voice transmission. Research indicates that copper core wire remains a preferred choice for applications requiring reliable performance and long-term stability (Refer to International Journal of Electrical Engineering Education, 2021).

Product After-Sales Service

Our after-sales service ensures customer satisfaction through responsive support and warranty coverage. We provide technical assistance, addressing any issues related to product installation or performance. Customers can reach out to our dedicated service team via email or phone for prompt resolution of inquiries.

Product Transportation

The RG11 coaxial cables with copper core wire are transported using robust packaging to prevent damage during transit. We utilize certified carriers to ensure timely and secure delivery to our customers, accommodating special shipping requirements when necessary.

Product Advantages

- Superior conductivity due to high-quality copper core wire.

- Durable and weather-resistant design suitable for outdoor use.

- Excellent support for high-frequency data and video transmissions.

- Reliable performance with a low signal loss over long distances.

Product FAQ

- What makes copper core wire preferable in RG11 cables? Copper core wire offers superior conductivity and durability, making it an ideal choice for RG11 cables that require efficient signal transmission over long distances.

- Can RG11 cables be used for outdoor applications? Yes, the design of RG11 cables, including their durable outer jacket, makes them suitable for outdoor trunk line applications.

- What is the minimum order quantity? The minimum order quantity for our RG11 coaxial cables with copper core wire is 50km.

- How does the tinned steel messenger enhance the cable? The tinned steel messenger provides additional support and prevents sagging, enhancing the cable's structural integrity when installed over long distances.

- Is there a warranty for these cables? Yes, we offer a warranty period to ensure that any manufacturing defects are addressed promptly.

- Can this cable handle high-frequency signals? Absolutely, RG11 coaxial cables designed with copper core wire are optimized for high-frequency signals, up to 3GHz.

- What certifications do these cables have? Our RG11 cables comply with CE, RoHS, and ISO standards, ensuring quality and safety.

- What industries commonly use RG11 cables? These cables are widely used in telecommunications, broadcast, and residential cable networks.

- Are there alternatives to copper core wire? While alternatives like aluminum exist, they typically have lower conductivity and require thicker cables to match copper's performance.

- How is the cable's impedance maintained? The characteristic impedance of 75 ohms is maintained through precise manufacturing processes, ensuring minimal signal reflection.

Product Hot Topics

- Understanding the Role of Copper Core Wire in Modern Cables

With the ever-growing demand for reliable and fast data transmission, the use of copper core wire in RG11 coaxial cables remains pivotal. Known for its excellent electrical conductivity, copper minimizes signal loss and enhances efficiency in data networks. Its mechanical strength and flexibility make it a preferred material in both residential and industrial applications. The ongoing advancements in copper processing technologies continue to improve the performance metrics of these cables, keeping them relevant in a market where new materials, such as fiber optics, are emerging. Nevertheless, the cost-effectiveness and proven reliability of copper core wire ensure its continued popularity in various sectors.

- The Environmental Impact of Copper Mining and Recycling

The production of copper core wire involves significant environmental implications, primarily due to the mining processes. As the industry seeks more sustainable solutions, recycling has become a focal point. Recycling copper not only reduces the environmental footprint but also lowers production costs. It's estimated that recycled copper consumes about 85% less energy than new copper production, showcasing a clear advantage. By integrating recycled copper into the manufacturing of RG11 cables, companies like Aston Cable minimize their environmental impact while maintaining the quality and performance of their products. This approach aligns with global sustainability goals and reflects a commitment to eco-conscious practices.

Image Description