Product Details

| Place of Origin | China |

|---|---|

| Brand Name | ASTON or OEM |

| Certification | SGS, CE, ROHS, ISO9001 |

| Daily Output | 200KM |

Common Product Specifications

| Product Name | Patch cord coaxial cable |

|---|---|

| Jackets | PVC |

| Color | Customized |

| Connectors | BNC DC Connector |

| Connector Material | Copper / CCS |

| Logo | OEM |

| Industrial Use | CCTV Cable |

| Origin | Hangzhou Zhejiang |

| Connector | BNC Connector add DC connector |

| Type | BNC male to male, DC male to female |

| Length | 20m/30m/40m/50m |

Product Manufacturing Process

Each RG59 outdoor cable is manufactured with precision and care in our factory. Utilizing advanced machinery including high-speed braiding machines, stranding machines, and ray machines, we ensure that every component of the cable is produced to the highest standards. The center conductor is meticulously constructed from solid copper or copper-clad steel. This is followed by a layer of dielectric insulation made from polyethylene to maintain signal integrity. Next, the shielding is applied, combining aluminum foil and braided wire for optimal protection against electromagnetic interference. Lastly, the outer jacket, made from UV-resistant PVC or polyethylene, is added to ensure the cable can withstand harsh outdoor conditions.

Product Application Scenarios

RG59 outdoor cable is versatile and is widely used in scenarios where reliable signal transmission is critical. Common applications include:

- CCTV Systems: Ideal for transmitting video signals from outdoor cameras to monitors or recording devices.

- Satellite and Cable TV: Suitable for connecting satellite dishes or cable systems to televisions.

- Low-Power Video and RF Applications: Used in other low-frequency applications where signal fidelity is less critical.

Product After-sales Service

We offer comprehensive after-sales support including a one-year warranty on all RG59 outdoor cables. Customers can contact our support team for troubleshooting and technical assistance. We also provide replacement services for defective products within the warranty period.

Product Transportation

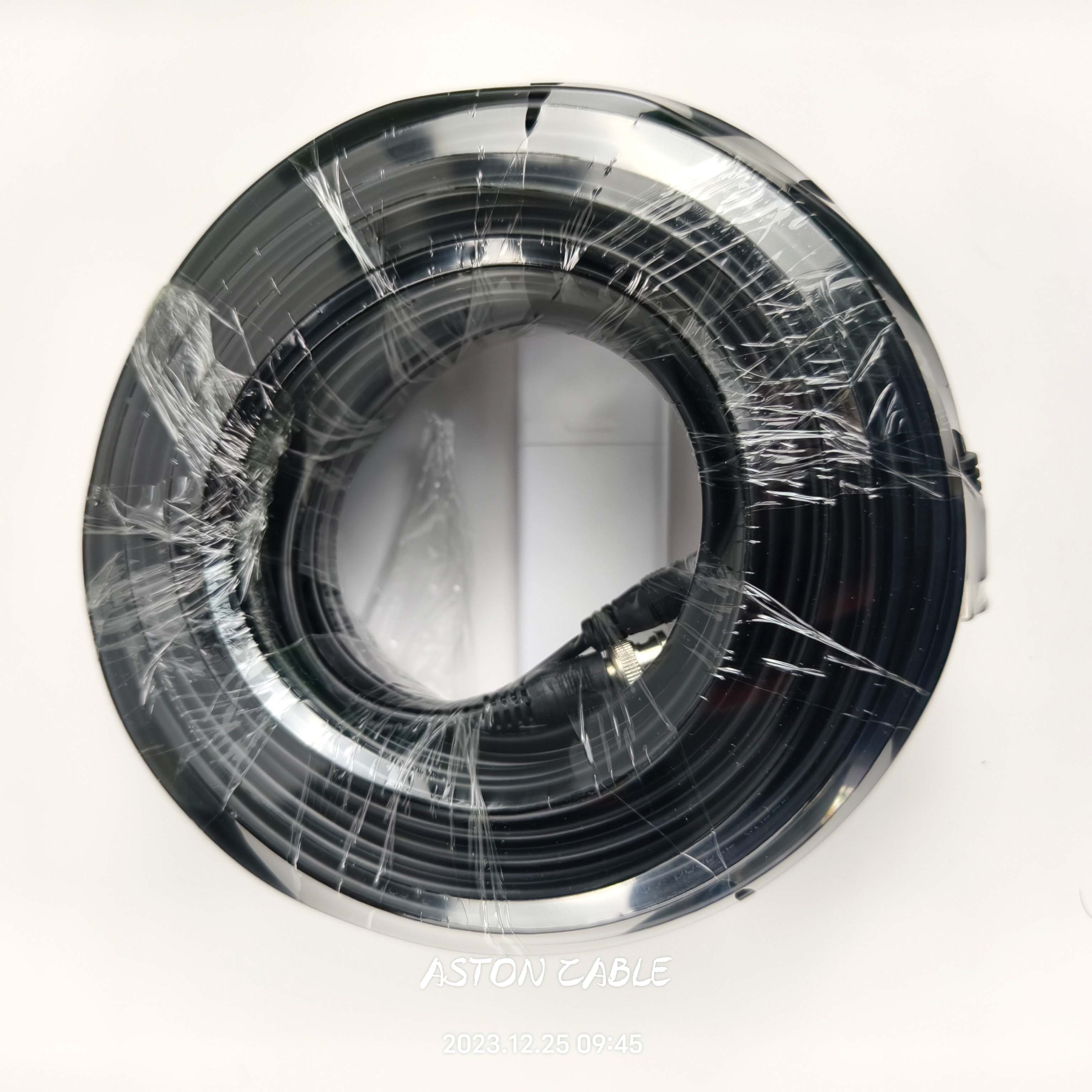

All our products are packaged securely to prevent any damage during transit. We offer various shipping options including air, sea, and express delivery to meet urgent requirements. Our logistics team ensures timely delivery and provides tracking details to customers.

Product Advantages

- Cost-Effective: Our RG59 outdoor cable is economically priced, making it an affordable option without compromising on quality.

- Flexibility: Easy to install, even in tight spaces, owing to its smaller diameter.

- Short-Distance Performance: Adequate for runs less than 750 feet, maintaining good signal quality.

Product FAQ

1. What is the maximum length for optimal performance of the RG59 outdoor cable?

For optimal performance, it is recommended to keep the length under 750 feet to avoid significant signal degradation.

2. Can this cable be used for high-frequency applications?

RG59 is better suited for low-frequency applications. For high-frequency needs, an RG6 cable is recommended.

3. How do you ensure the quality of the RG59 outdoor cable?

Our factory employs stringent quality control practices, including 100% testing and the use of high-grade materials like copper conductors and UV-resistant jackets.

4. Is this cable compliant with international standards?

Yes, our RG59 outdoor cables are RoHS, CE, and ISO9001 certified, ensuring compliance with international standards.

5. What materials are used in the construction of the connectors?

We use high-quality copper for all connectors to ensure durability and superior conductivity.

6. Can the cable operate in harsh weather conditions?

Yes, the outer jacket is made from UV-resistant PVC or polyethylene, making the cable suitable for extreme weather conditions.

7. How do you prevent signal loss during installation?

Proper installation practices, including avoiding parallel runs with high-voltage lines and ensuring proper grounding, can minimize signal loss.

8. What’s the daily production capacity of your factory?

Our factory has a daily production capacity of around 200KM for RG59 outdoor cables.

9. Can I customize the color of the outer jacket?

Yes, we offer customization options for the color of the outer jacket to meet specific customer requirements.

10. How can I place an order?

You can contact our sales team via email or phone. We offer flexible payment options and timely delivery services.

Product Hot Topics

1. Best practices for installing RG59 outdoor cables?

When installing RG59 outdoor cables, ensure that all connectors and junctions are weatherproofed. Avoid running the cables parallel to high-voltage lines to minimize interference. Proper grounding is also essential for optimal performance. Use cable ties to secure the cable and prevent any undue stress on the connectors. These best practices help in maintaining signal integrity and extending the life of the cable.

2. How does RG59 compare to RG6 for outdoor use?

RG59 cables are more flexible and generally less expensive than RG6 cables, making them a cost-effective solution for short to medium distances. However, RG6 cables provide better performance for longer distances and higher-frequency applications. When choosing between the two, consider the distance and specific requirements of your installation.

3. Understanding the structure of RG59 outdoor cable?

The RG59 outdoor cable consists of a center conductor made of solid copper or copper-clad steel, surrounded by dielectric insulation, shielding layers made from aluminum foil and braided wire, and an outer jacket of UV-resistant PVC or polyethylene. Each layer plays a crucial role in ensuring signal integrity and protecting against environmental factors.

4. Benefits of using RG59 cables in CCTV systems?

RG59 cables are ideal for CCTV systems due to their cost-effectiveness, flexibility, and adequate performance for short to medium distances. They provide reliable video signal transmission, making them a popular choice for security installations. Additionally, the RG59 outdoor cable's weather-resistant properties make it suitable for external CCTV setups.

5. Importance of proper grounding in RG59 outdoor cable installations?

Proper grounding is crucial in RG59 outdoor cable installations to prevent signal degradation and protect against electrical surges. Grounding helps in minimizing interference and ensures the long-term reliability of the cable. It is a critical step in the installation process that should never be overlooked.

6. What makes our factory’s RG59 cables stand out?

Our factory's RG59 cables stand out due to their high-quality materials, stringent quality control measures, and compliance with international standards such as RoHS, CE, and ISO9001. We use advanced manufacturing processes and offer customization options to meet specific customer needs. Our focus on customer satisfaction and reliable performance sets our products apart from competitors.

7. How to ensure weatherproofing of RG59 outdoor cable connections?

To ensure weatherproofing of RG59 outdoor cable connections, use weatherproof connectors and junction boxes. Apply sealing tape or heat shrink tubing around the connections to prevent moisture ingress. Regularly inspect the connections for any signs of wear or damage, and replace any compromised components promptly to maintain signal integrity.

8. Can RG59 cables be used for satellite TV installations?

Yes, RG59 cables can be used for satellite TV installations, particularly for short to medium distance runs. They are suitable for connecting satellite dishes to individual TVs or distribution points. However, for longer distances or higher-frequency signals, RG6 cables may be a better choice due to their superior performance.

9. Tips for running RG59 cables in tight spaces?

When running RG59 cables in tight spaces, take advantage of the cable's flexibility. Use cable ties to secure the cable and prevent bending or kinking. If necessary, use cable lubricant to ease the installation process. Plan the cable route in advance to avoid any obstacles and ensure a smooth installation.

10. What to consider when customizing RG59 outdoor cables?

When customizing RG59 outdoor cables, consider the specific requirements of your installation, such as the length, outer jacket color, and connector types. Communicate these details clearly to the manufacturer to ensure the final product meets your needs. Additionally, ensure that the customization does not compromise the cable's performance or compliance with relevant standards.

Image Description