Product Main Parameters

| Type | RG6 with power cable |

| Conductor | 1.02mm 18AWG CCS |

| Dielectric | 4.6FPE |

| Jackets | PVC/Black PE |

| Color | Customized |

| Weight | 6.0KG/100m |

| Packages | Coil reel, plastic drum, wooden drum, color boxes, carton boxes |

Common Product Specifications

| Place of Origin | China |

| Brand Name | ASTON or OEM |

| Certification | SGS CE ROHS ISO9001 |

| Minimum Order Quantity | 30km |

| Supply Ability | 25000KM/Per year |

| Delivery Port | Ningbo |

Product Manufacturing Process

The manufacturing process of RG6 cables involves several precise steps to ensure quality and reliability. Initially, the conductive material, either copper-clad aluminum (CCA) or pure copper, is drawn into fine strands. CCA offers cost and weight advantages over pure copper, but with slightly reduced conductivity. These strands are then braided around an insulating layer to form a shield, providing protection against external electromagnetic interference. The shield is critical, especially for high-frequency applications. Following the shielding process, the cable is encased in a durable jacket, typically made from PVC or PE, which offers additional protection and flexibility. Finally, rigorous testing is performed to ensure the cables meet industry standards for signal transmission and durability. The choice between CCA and pure copper depends on the application's specific requirements—CCA for cost efficiency and lighter weight, or pure copper for superior conductivity and durability.

Product Application Scenarios

RG6 cables are vital in a variety of applications due to their ability to effectively carry high-frequency signals. These cables are commonly used in CATV, satellite, and TV antenna systems, where efficient signal transmission is essential. The debate between CCA vs pure copper is significant in scenarios demanding different performance levels. For instance, in high-demand settings like broadcasting and surveillance systems, pure copper's superior conductivity offers reliable and high-quality signal transmission, making it a preferred choice despite its higher cost. Conversely, CCA might be chosen for home installations where budget constraints are a concern, and the performance demands are not as critical. Understanding each material's benefits allows suppliers to tailor solutions effectively to meet diverse application needs.

Product After-Sales Service

Our commitment to quality extends beyond manufacturing. We provide comprehensive after-sales support to ensure customer satisfaction. This includes technical assistance, troubleshooting, and replacement services if necessary. We strive to resolve any issues promptly and maintain open communication channels for continuous support.

Product Transportation

Products are carefully packaged in accordance with international shipping standards to prevent damage during transit. Typically, cables are wound on wooden drums for safety and ease of handling. We offer various shipment options, including air and sea freight, to accommodate different delivery timelines and budgets.

Product Advantages

- High Quality: As a leading supplier, our RG6 cables offer excellent performance for both CCA vs pure copper materials.

- Customized Solutions: We provide tailored solutions to meet specific project requirements, ensuring optimal performance and cost-effectiveness.

- Reliability: Our cables are rigorously tested to meet and exceed industry standards, ensuring reliability and durability in all applications.

Product FAQ

- What are the main differences between CCA and pure copper RG6 cables?

CCA cables are lighter and cheaper, making them ideal for applications where budget is a concern, while pure copper offers superior conductivity and durability for high-demand environments. - How should I choose between CCA and pure copper cables?

Consider factors such as budget, application demand, and environmental conditions. Pure copper is preferred for high-performance needs, while CCA suits cost-constrained projects. - Are your cables compliant with industry standards?

Yes, our cables comply with RoHS, CE, and IEC standards, ensuring quality and safety across all applications. - What is the MOQ for RG6 cables?

The minimum order quantity is 30km, allowing us to maintain efficient production and supply chains. - What type of jacket materials are available?

We offer PVC for indoor use and black PE for outdoor installations, catering to diverse environmental conditions. - Can I customize the color of the cables?

Yes, we offer customization options for the cable color to meet specific aesthetic or branding preferences. - What is the delivery time for orders?

Delivery times vary based on order size and location, but we strive to provide timely shipments for all customer orders. - Do you provide technical support?

Yes, we offer comprehensive technical support to assist with installation and troubleshooting as needed. - Are your products environmentally friendly?

Our products comply with environmental standards such as RoHS, ensuring that they are safe and non-harmful to the environment. - What packaging options are available?

We provide multiple packaging options, including coil reels, plastic drums, and wooden drums, to suit different handling and transportation requirements.

Product Hot Topics

- The Importance of Choosing the Right Supplier for Your RG6 Cables

Selecting the right supplier is crucial for ensuring the quality and reliability of RG6 cables. A reputable supplier will provide not only high-quality materials, whether CCA or pure copper, but also comprehensive after-sales support and customization options. When evaluating suppliers, consider their manufacturing capabilities, compliance with industry standards, and ability to meet your specific application needs. - CCA vs Pure Copper: Which Material is Best for Your Application?

The ongoing debate between CCA and pure copper for RG6 cables centers on factors such as cost, weight, and performance. CCA, being more affordable and lighter, is often chosen for budget-sensitive projects, while pure copper is favored for applications requiring maximum conductivity and reliability. Understanding these materials' properties can guide you in making informed decisions tailored to your project's requirements.

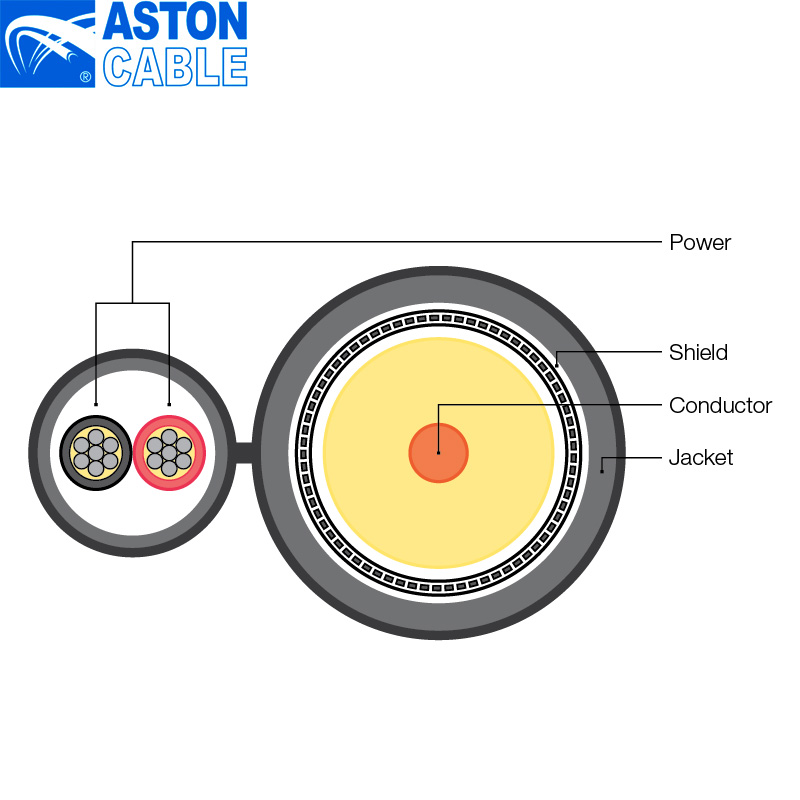

Image Description