Product Main Parameters

| Parameter | Details |

|---|---|

| Conductor | Bare copper, fine wire strand |

| Core Insulation | PVC compound TI1 |

| Braid | Tinned copper wire |

| Nominal Voltage | 300 / 500 V |

| Temperature Range | -5 to 70°C (flexible), -40 to 80°C (fixed) |

| Flame Retardant | IEC 60 332.1 compliant |

Common Product Specifications

| Type | Outdoor Diameter (mm) | Weight (kg/km) |

|---|---|---|

| CY 3G0.5 | 6.1 | 59 |

| CY 4G0.5 | 6.5 | 71 |

| CY 5G0.5 | 7.0 | 86 |

| CY 7G0.5 | 7.5 | 105 |

Product Manufacturing Process

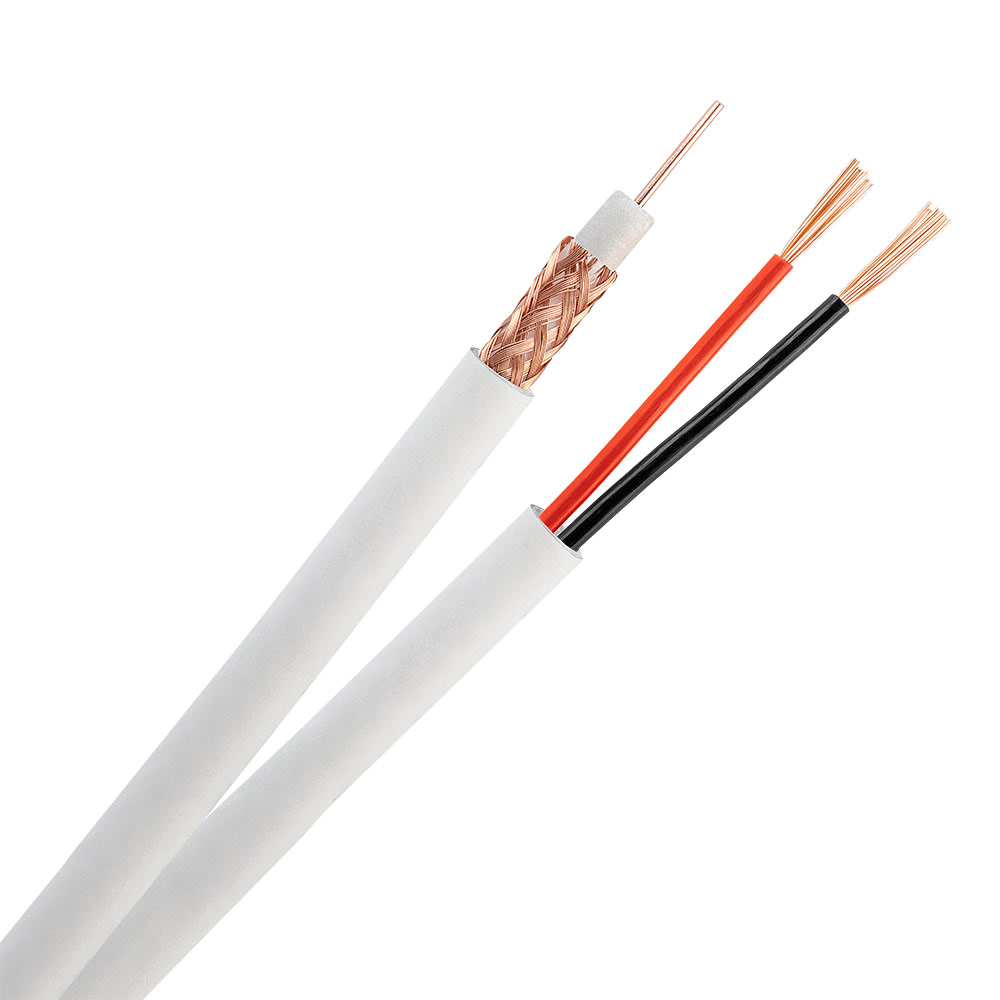

Composite cables for access control are manufactured by integrating multiple types of wires—such as power wires, data cables, and potentially video transmission cables—within a single sheath. The manufacturing process involves several stages, starting with the selection of high-quality materials. Conductors are made from fine stranded copper, then insulated with PVC or cross-linked polyethylene for durability and safety. The cables are braided with tinned copper wires to enhance electromagnetic compatibility. The outer sheath is applied in compliance with IEC and VDE standards, ensuring flame retardancy and mechanical protection. Each stage of manufacturing undergoes strict quality checks to ensure compliance with international standards such as ISO9001 and RoHS. The precise engineering and quality control in the manufacturing process make these composite cables reliable for various complex installations.

The result is a robust, versatile cable capable of handling power, data, and possibly video transmissions within a streamlined setup. Such design innovations are crucial in meeting modern infrastructure demands, providing efficiency and reliability in access control systems.

Product Application Scenarios

Composite cables for access control are integral to modern security systems. These cables are widely used in corporate offices, educational campuses, healthcare facilities, and government buildings. The multifunctional nature of composite cables reduces installation complexity by combining power, data, and video capabilities within a singular cable, simplifying cable management and reducing points of failure. Moreover, in environments requiring high data integrity and security, such as data centers or research facilities, the use of composite cables ensures robust and reliable operations.

Composite cables also support a broad range of applications including connecting access control panels with peripheral devices like card readers and keypads, and transmitting video signals for surveillance systems. This flexibility makes them an ideal choice for retrofitting existing systems or deploying new installations where minimizing installation time and costs is crucial. The strategic deployment of composite cables ensures enhanced performance and security in varied application scenarios.

Product After-Sales Service

- Technical Support: Access to a professional support team for installation and maintenance queries.

- Warranty: Comprehensive warranty covering manufacturing defects, ensuring peace of mind for suppliers and end-users.

- Replacement and Repair: Prompt replacement or repair options in case of cable failures.

- Customer Training: Training sessions for suppliers on best practices for composite cable installation and maintenance.

Product Transportation

Shipping of composite cables involves carefully packing to prevent damage during transit. Given the bulk and weight, cables are usually wound on large reels and securely fastened for shipment. Our suppliers ensure compliance with international shipping standards and offer flexible delivery options tailored to customer needs. The delivery ports, such as Ningbo, facilitate efficient logistics for timely arrivals worldwide.

Product Advantages

- Simplified Installation: Composite cables reduce the need for multiple cable runs, lowering installation time.

- Cost-Efficiency: Though potentially higher in upfront cost, these cables save on labor and material expenses.

- Space-Saving: Ideal in environments with limited space, reducing cable clutter significantly.

- Improved Aesthetics: A single cable run offers a cleaner, more organized installation.

- Enhanced Reliability: Fewer connectors reduce failure points, improving system reliability.

Product FAQ

- What are the primary components of composite cables?

Composite cables typically include power wires for low-voltage electricity, data cables using twisted pairs to reduce interference, and sometimes coaxial or fiber optic cables for video transmission. This integration supports comprehensive access control system operations. - Why choose composite cables over traditional wiring?

Composite cables simplify installation by bundling necessary functionalities into one. This not only reduces installation time and complexity but also minimizes potential points of failure, offering a robust solution for access control systems. - Can composite cables be used outdoors?

Yes, provided they are equipped with UV protection to withstand environmental conditions. Suppliers should ensure appropriate ratings for specific installation environments, such as plenum rating in HVAC spaces. - Are composite cables compatible with existing access control systems?

Composite cables are designed to integrate seamlessly with most modern access control system components. It is crucial to verify compatibility with specific system requirements before selection. - Do composite cables require special installation tools?

While standard cabling tools are used, it is essential that installers have technical knowledge of composite cables to ensure proper installation and maintenance. - What factors should be considered for optimal composite cable selection?

Quality, compatibility, and environmental conditions must be considered. High-quality cables ensure data integrity and prevent power loss, while specific ratings may be necessary for challenging environments. - How do composite cables contribute to system reliability?

By reducing installation complexity and minimizing connections, composite cables enhance system reliability, offering robust performance in varied applications. - Do composite cables support video transmission?

Yes, many composite cables include coaxial or fiber optic components to transmit video signals for integrated surveillance systems within access control setups. - Are composite cables cost-effective?

Despite a potentially higher initial cost, composite cables offer long-term savings by reducing labor, material, and maintenance costs, proving cost-effective in large installations. - What is the expected lifespan of composite cables?

When installed correctly and maintained properly, composite cables can serve reliably for many years, supported by the warranty and technical guidance from suppliers.

Product Hot Topics

- Installation Tips for Composite Cables

When installing composite cables for access control, careful planning is key. Suppliers suggest designing a thorough layout plan, accounting for the unique cable thickness and required bending radii. Ensure clear communication with all parties involved to coordinate effectively during installation. It's often beneficial to conduct pre-installation training sessions to familiarize the installation team with any nuances specific to composite cable deployment. Thorough testing post-installation is also crucial to verify the integrity of the setup. - Composite Cables vs. Traditional Wiring

The debate about using composite cables over traditional wiring continues among suppliers and end-users. While traditional wiring might appeal due to familiarity, composite cables offer a modern and efficient alternative. By integrating power, data, and video capabilities in one cable, they significantly reduce clutter and installation time while enhancing reliability. Customers have praised these benefits, especially in complex installations where traditional solutions become cumbersome. Over time, the cost-effectiveness and reduced maintenance requirements of composite cables have shifted many towards this innovative solution. - Advancements in Composite Cable Technology

Recent advancements in composite cable technology have seen a surge in interest from suppliers. Innovations include better insulation materials for higher durability and advanced shielding techniques for enhanced data integrity. With an increasing demand for smart building solutions, composite cables are adapting to support IoT integration seamlessly. These technological strides ensure composite cables remain at the forefront of access control solutions, meeting the ever-evolving needs of businesses worldwide.

Image Description