Product Main Parameters

| Parameter | Detail |

|---|---|

| Voltage Rating | 300/500V |

| Test Voltage | 4kV |

| Temperature Rating (Fixed) | -40°C to 80°C |

| Temperature Rating (Flexed) | -5°C to 70°C |

| Minimum Bending Radius (Fixed) | 4 × overall diameter |

| Minimum Bending Radius (Flexed) | 12.5 × overall diameter |

Common Product Specifications

| No. of Cores | Nominal Cross Sectional Area (mm²) | Nominal Overall Diameter (mm) |

|---|---|---|

| 2 | 0.75 | 7.2 |

| 3 | 1.0 | 7.9 |

| 4 | 1.5 | 9.2 |

Product Manufacturing Process

The manufacturing of SY Armored PVC control cables involves a series of precise steps starting with the selection of high-quality raw materials, including copper for conductors and PVC for insulation. The process continues with the stranding of conductors, insulation of wires, and application of the galvanised steel wire braid for mechanical protection. The final steps involve the extrusion of the outer PVC sheath and rigorous testing to ensure adherence to quality standards. According to industry studies, it is crucial to maintain strict quality control measures at every stage to enhance cable durability, flexibility, and performance in cable control systems.

Product Application Scenarios

SY Armored PVC control cables are extensively used in various sectors due to their durability and flexibility. In the industrial machinery domain, these cables facilitate control operations where direct mechanical linkages are impractical. The aviation industry relies on these cables to ensure precise control surface movements, while in automotive and marine applications, they provide reliable performance in steering and throttle systems. Industry reports underscore the importance of using high-quality cables to maintain system efficiency and safety, especially in environments demanding stringent control over machinery.

Product After-Sales Service

Our suppliers prioritize customer satisfaction through comprehensive after-sales support, including consultation services, installation guidance, and troubleshooting assistance. Warranty services are available to address any product defects or performance issues.

Product Transportation

SY control cables are securely packaged to ensure safe transportation, with options for bulk shipping and customized logistics solutions to meet diverse supplier needs.

Product Advantages

- Flexibility: Ideal for routing in complex environments, reducing installation difficulties for suppliers.

- Lightweight: Supports applications requiring minimal weight, such as in cable control systems for aerospace.

- Cost-Efficiency: Offers a budget-friendly option for control systems without compromising quality.

- Simple Construction: Enhances reliability, making it a preferred choice for suppliers in various industries.

Product FAQ

- What are SY control cables used for?

These cables are widely used in cable control applications, such as instrumentation and industrial machinery, offering flexibility and resistance to mechanical stress, a key aspect suppliers prioritize in product selection.

- Are these cables suitable for outdoor use?

No, SY control cables are not designed for outdoor or underground installations. Suppliers should consider alternative products for such applications.

- Can these cables be used in fixed wiring applications?

No, they aren't suitable for fixed wiring that requires compliance with BS7671. Suppliers should advise on alternative options for such needs in cable control systems.

- What is the temperature range for these cables?

SY control cables operate effectively between -40°C to 80°C when fixed, and -5°C to 70°C when flexed, providing adaptable solutions for suppliers in various environments.

- What is the minimum bending radius?

The minimum bending radius is 4 times the overall diameter when fixed and 12.5 times when flexed, a critical detail for suppliers considering installation environments.

- Are the cables shielded?

Yes, they have a galvanised steel wire braid that provides mechanical protection and electromagnetic interference shielding, a significant feature for cable control system suppliers.

- What standards do these cables comply with?

They meet ISO9001, RoHS, CE, and IEC standards, ensuring high quality and safety, which are essential commitments for suppliers.

- How often should these cables be inspected?

Regular inspections are recommended to check for wear and tear, particularly in demanding cable control applications. Suppliers should guide on maintenance schedules.

- What are the delivery options?

Cables can be shipped in bulk or according to supplier specifications, with delivery ports primarily in Ningbo to facilitate international logistics.

- What is the typical lead time?

Lead times can vary based on order quantity and supplier logistics, but we strive for efficient processing to meet demands promptly.

Product Hot Topics

- How SY Control Cables Enhance Industrial Automation

In the realm of industrial automation, SY control cables are pivotal, providing consistent performance and reliability that suppliers value. Their flexibility, lightweight nature, and protective braiding make them indispensable for complex machinery layouts. Suppliers emphasize these attributes, promoting their application in various automation settings where precision and durability are non-negotiable.

- Environmental Considerations for Cable Control Systems

Suppliers often face challenges in sourcing cables that withstand harsh environmental conditions. The SY control cable's robust design, offering resistance to moisture and mechanical stress, makes it a preferred choice. Industry discussions often highlight the importance of selecting materials that ensure longevity and performance, principles that guide suppliers in advising their clients.

- Trends in Cable Control Manufacturing

Manufacturing trends indicate a shift towards more sustainable and efficient production methods for cable control systems. Suppliers see a growing demand for cables that not only perform well but also align with eco-friendly practices. The SY cable's compliance with RoHS and other environmental standards position it as a forward-thinking option for environmentally conscious suppliers.

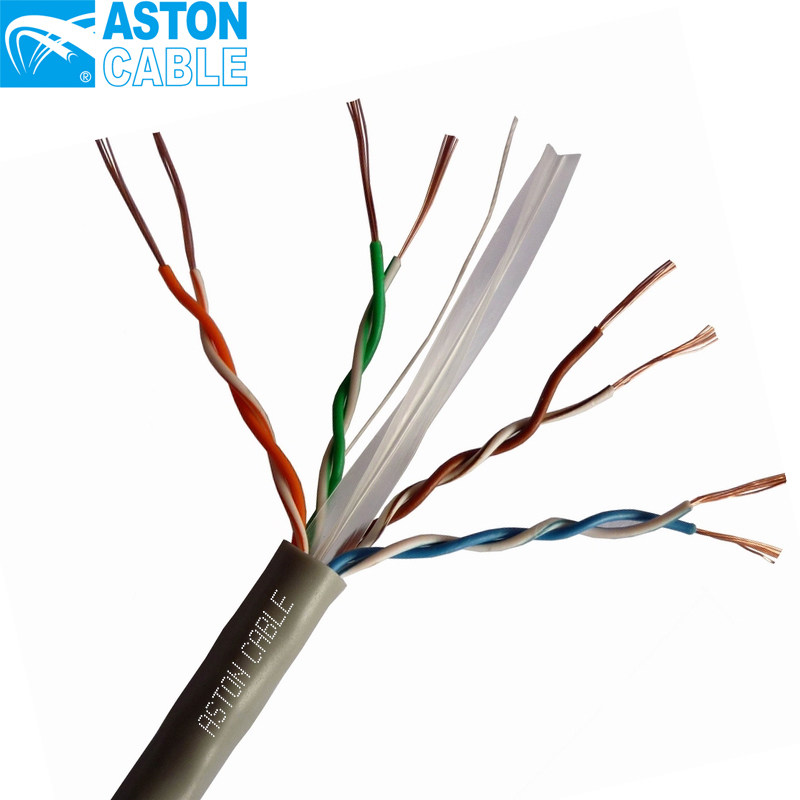

Image Description