Product Main Parameters

| Parameter | Specification |

|---|---|

| Voltage Rating | 300/500V |

| Test Voltage | 4kV |

| Temperature Rating (Fixed) | -40°C to 80°C |

| Temperature Rating (Flexed) | -5°C to 70°C |

| Minimum Bending Radius (Fixed) | 4 × overall diameter |

| Minimum Bending Radius (Flexed) | 12.5 × overall diameter |

Common Product Specifications

| No. of Cores | Cross Sectional Area (mm²) | Overall Diameter (mm) | Weight (kg/km) |

|---|---|---|---|

| 4 | 0.75 | 8.0 | 107 |

| 4 | 1.0 | 8.5 | 124 |

| 4 | 1.5 | 9.2 | 151 |

| 4 | 2.5 | 11.1 | 230 |

| 4 | 4.0 | 13.2 | 332 |

Product Manufacturing Process

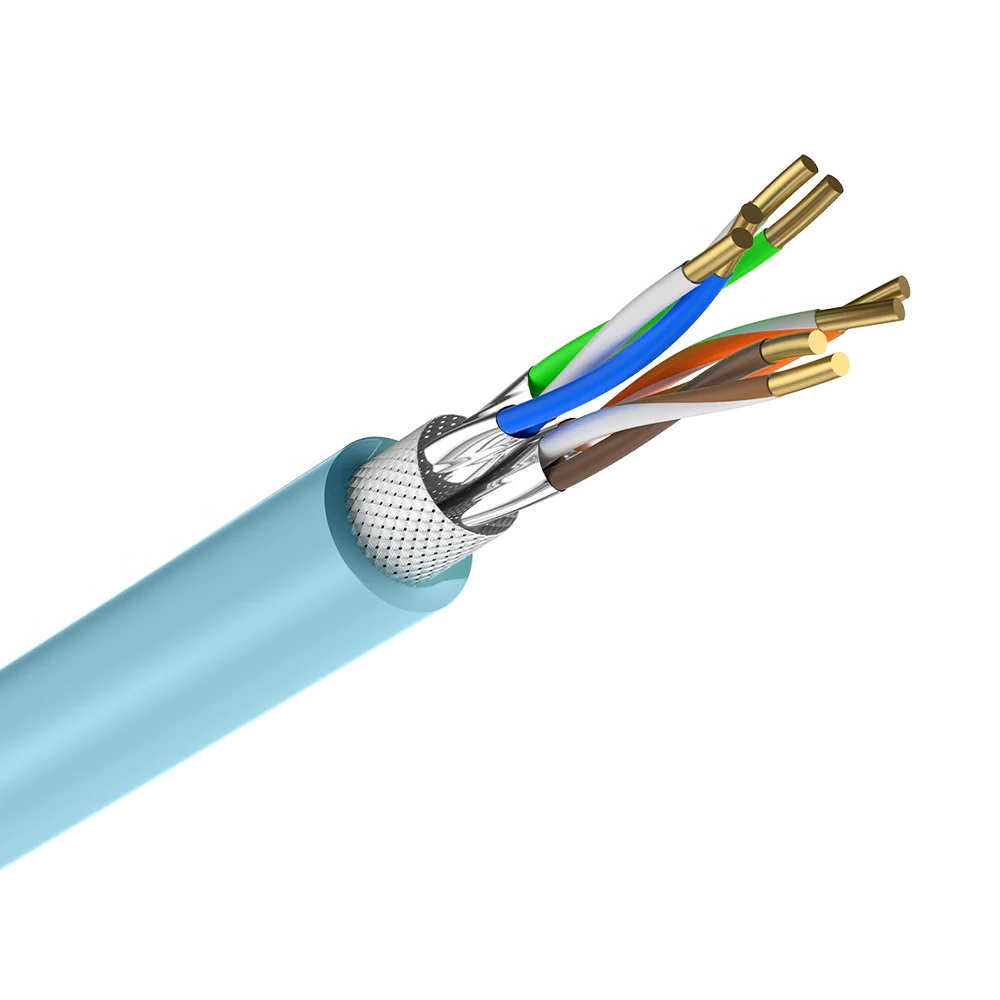

According to authoritative industry papers, the manufacturing process of 4 core control cables involves several key stages. Initially, high-quality copper or aluminum is drawn into fine strands for the conductors. These conductors are then stranded to enhance flexibility. Each conductor is insulated with materials such as PVC, XLPE, or EPR to ensure electrical safety and signal integrity. The insulated conductors are then bundled and encased in a durable outer sheath, often with an additional metal armoring layer for mechanical protection. Advanced manufacturing techniques and quality control systems are employed to maintain the highest standards of performance and reliability.

Product Application Scenarios

Based on authoritative sources, 4 core control cables are vital in various industrial and commercial settings. In control panels, they link components, ensuring seamless communication and machinery regulation. They are integral to automation systems, facilitating signal flow between sensors, actuators, and control units. In transport, they're crucial for elevator and escalator control systems. Additionally, these cables are pivotal in industrial machinery for handling numerous signals efficiently, and in building management systems, they transmit signals for controlling HVAC, lighting, and more.

Product After-Sales Service

Our suppliers offer comprehensive after-sales services for the 4 core control cables, including product support, installation guidance, and troubleshooting assistance. Customers can rely on prompt responses and expert advice to ensure the optimal performance of their cable installations.

Product Transportation

Transportation of 4 core control cables is managed to prevent any damage during delivery. Suppliers ensure proper packaging and handling, opting for logistics solutions that maintain the cables' integrity from the factory to the customer. All shipments are tracked for customer convenience and assurance.

Product Advantages

- Efficient Signal Transmission: 4 core control cables streamline the transmission of multiple signals, reducing installation complexity.

- Flexible and Versatile: Stranded conductors and varied sheath materials offer adaptability across various applications.

- Durability: Robust design and materials ensure resistance to environmental factors, supporting long-term use.

- Compact Design: Consolidated conductors minimize space requirements and installation clutter.

Product FAQ

- Q1: Can these cables be used outdoors?

A1: While 4 core control cables are highly durable, they are typically not recommended for outdoor applications unless specifically armored for such conditions. Suppliers advise consulting specific product guidelines for outdoor usage.

- Q2: Are the cables flame-retardant?

A2: Yes, many 4 core control cables supplied are designed with flame-retardant properties, ensuring safety in hazardous environments. It's essential to confirm this feature with the suppliers when ordering.

- Q3: What is the typical lead time for bulk orders?

A3: Lead times vary depending on the order size and supplier. However, suppliers typically maintain a large inventory, allowing for swift order fulfillment. Customers should confirm specific details with their chosen supplier.

- Q4: Is customization available?

A4: Yes, many suppliers offer customization options for 4 core control cables, including length, color, and marking. Customers can discuss their specific requirements directly with suppliers to ensure tailored solutions.

- Q5: How do these cables ensure signal integrity?

A5: 4 core control cables maintain signal integrity through high-quality insulation and sheathing materials, minimizing interference and signal loss. This design element is crucial for efficient industrial communication.

- Q6: What testing is performed on these cables?

A6: Suppliers conduct extensive testing, including voltage rating, temperature resistance, and durability, to ensure each cable meets industry standards and customer expectations.

- Q7: How are the cables packaged for shipping?

A7: Cables are carefully coiled and packed in robust protective materials to prevent damage during transit. Suppliers prioritize secure packaging to maintain product integrity during shipping.

- Q8: Can these cables be used in high-temperature environments?

A8: Most 4 core control cables are rated for specific temperature ranges and can be used in moderately high-temperature environments. Customers should verify temperature specifications with their suppliers for high-heat applications.

- Q9: What colors are available for these cables?

A9: Suppliers generally offer standard colors such as gray and black. However, custom colors may be available upon request, enabling buyers to match specific project requirements.

- Q10: What certifications do these cables have?

A10: The cables typically comply with international standards such as RoHS, CE, and IEC, ensuring high quality and safety. Customers should confirm specific certifications with their chosen supplier.

Product Hot Topics

- How Suppliers Ensure Cable Quality

Leading 4 core control cable suppliers prioritize quality by sourcing superior raw materials and employing advanced manufacturing techniques. Rigorous testing processes further assure cable reliability, meeting stringent international standards. Buyers can trust these suppliers to deliver cables that perform optimally across various industrial applications.

- Innovations in Control Cable Technology

Recent advancements have driven control cable technology forward, with suppliers integrating cutting-edge insulation materials and manufacturing methods. These innovations enhance cable performance, offering greater durability and efficiency in signal transmission. Industry professionals continue to seek suppliers at the forefront of these developments.

- Choosing the Right Supplier for Control Cables

Selecting the right supplier is crucial for acquiring high-quality 4 core control cables. Key factors include supplier reputation, product range, customization options, and after-sales support. Partnering with trusted suppliers promises reliable performance and customer satisfaction.

- The Role of Control Cables in Industrial Automation

4 core control cables are essential in industrial automation, linking vital components and ensuring seamless operations. Suppliers provide cables designed to withstand demanding environments, crucial for maintaining efficiency and productivity in automated systems.

- Environmental Considerations in Cable Production

Environmental sustainability is increasingly important in cable production. Suppliers are adopting eco-friendly practices, such as using recyclable materials and minimizing waste. This approach assures buyers of an environmentally responsible sourcing choice for 4 core control cables.

- Understanding Cable Certifications and Standards

When selecting suppliers, understanding cable certifications and standards is vital. Reputable suppliers provide detailed compliance information, ensuring their 4 core control cables meet international quality and safety benchmarks. This knowledge empowers informed purchasing decisions.

- Customizing Cables for Specialized Applications

Suppliers offer a range of customization options, allowing for bespoke cable solutions tailored to specific project needs. From length and color to sheath material and marking, customization ensures that 4 core control cables precisely meet application requirements.

- The Future of Cable Technology

As industries evolve, the demand for advanced cable solutions grows. Suppliers are investing in R&D to innovate new materials and designs, promising enhanced performance and adaptability. Buyers can anticipate continued advancements in 4 core control cable technology.

- Ensuring Long-Term Cable Performance

Suppliers emphasize the importance of proper installation and maintenance for long-term cable performance. By following supplier guidelines, buyers can extend the lifespan of their 4 core control cables, ensuring sustained efficiency and reliability.

- Advancements in Cable Material Science

Material science breakthroughs are transforming the cable industry. Suppliers are adopting new materials that offer superior insulation, flexibility, and strength, setting new standards for the performance and durability of 4 core control cables in demanding environments.

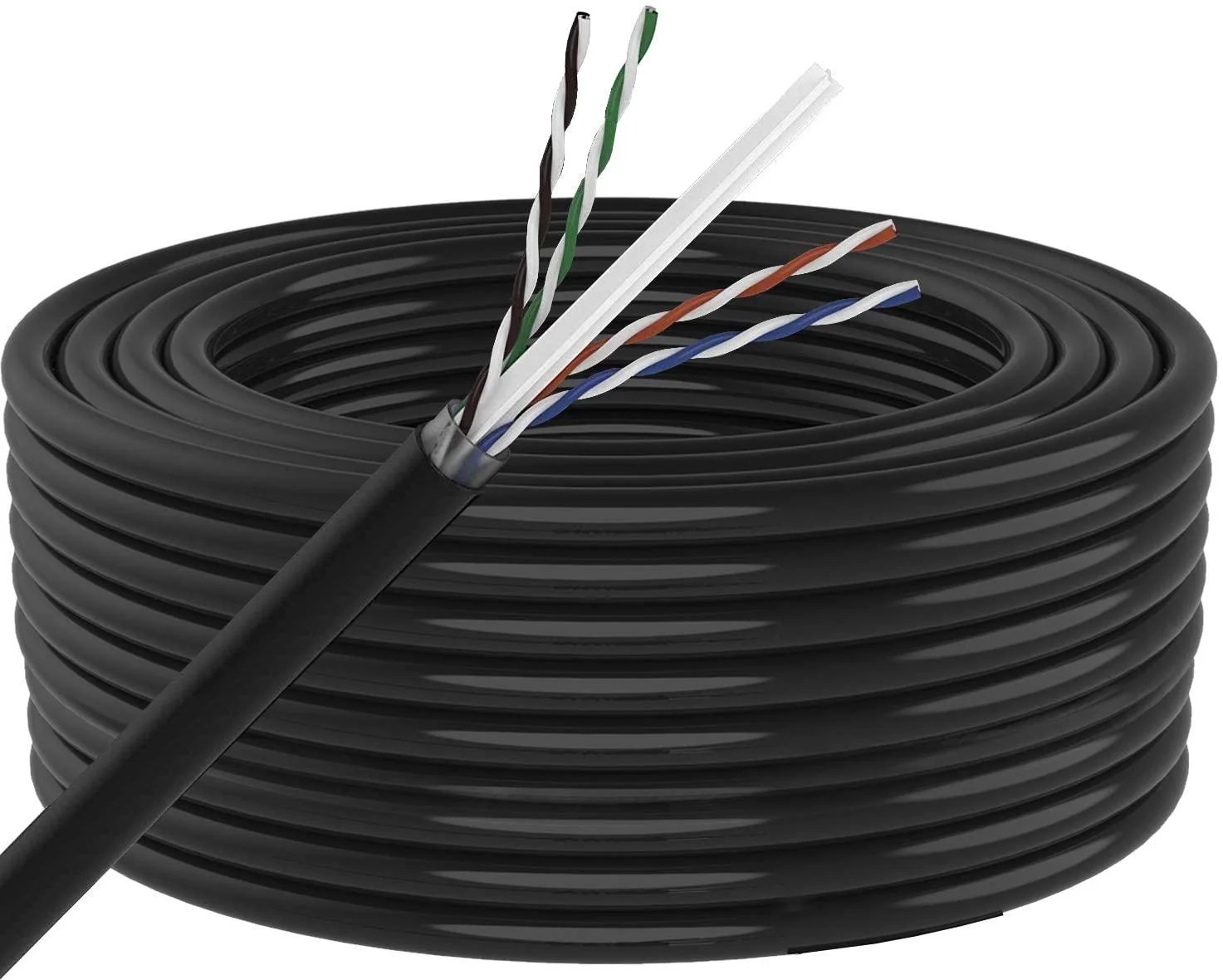

Image Description