Product Main Parameters

| Parameter | Specification |

|---|---|

| Conductor Material | CCAM Wire |

| Conductor Size | 23AWG |

| Data Rate | 10Gbps |

| Bandwidth | 600MHz |

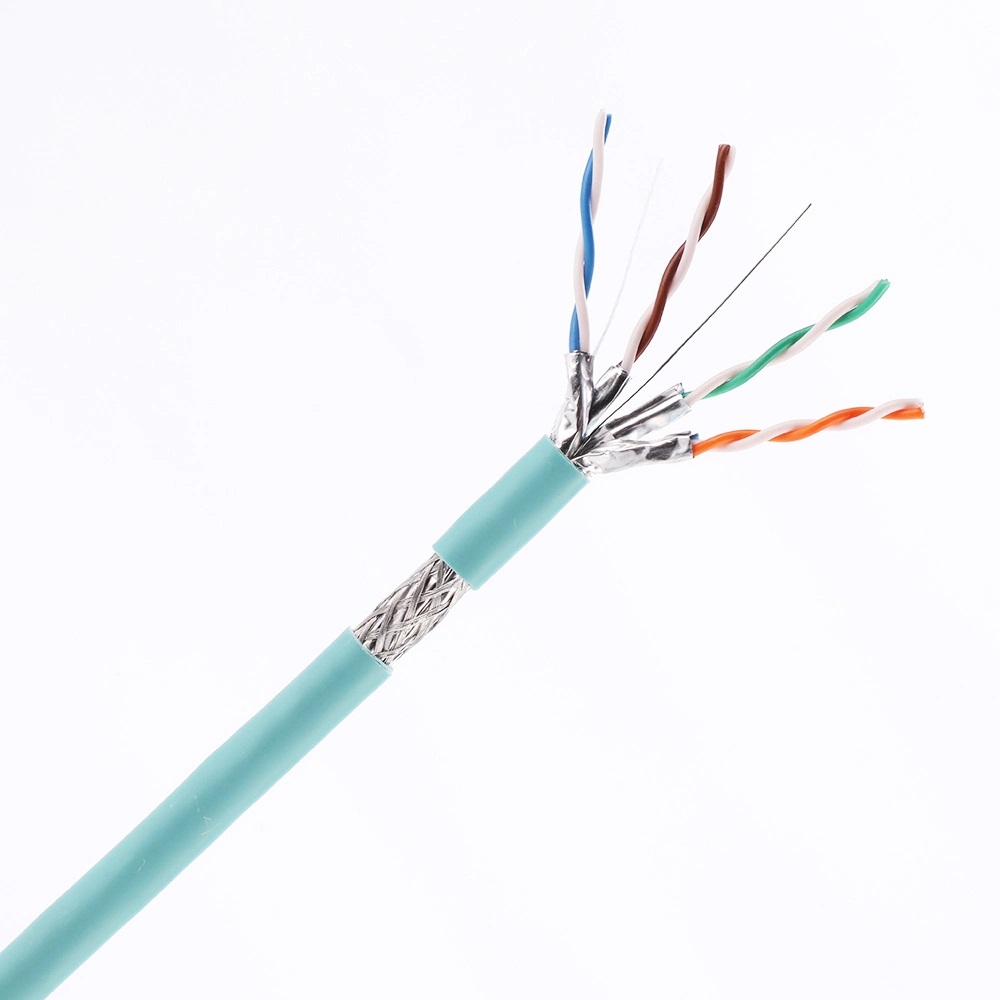

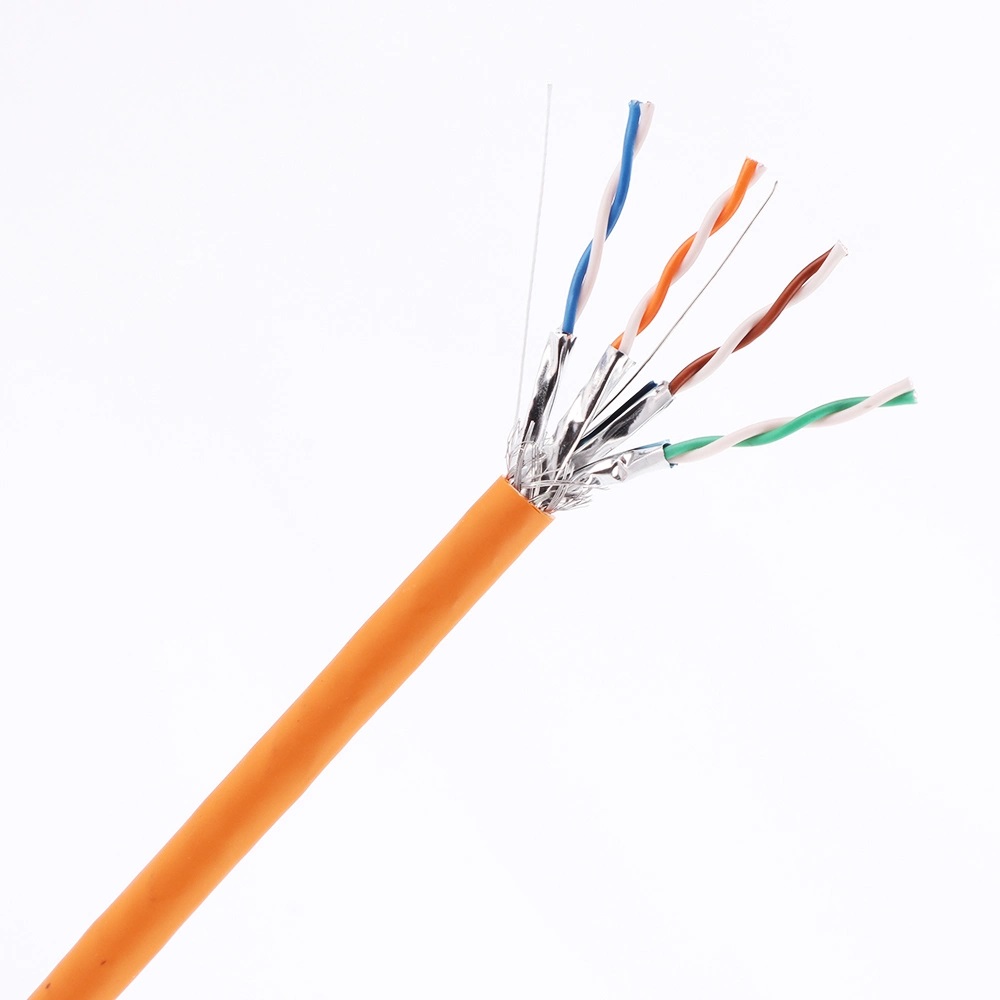

| Cable Structure | S/FTP |

| Jackets Available | PVC, LSZH |

| Origin | China |

Common Product Specifications

| Specification | Detail |

|---|---|

| Color | Customized |

| Logo | OEM |

| Minimum Order Qty | 100 rolls |

| Daily Output | 200KM |

Product Manufacturing Process

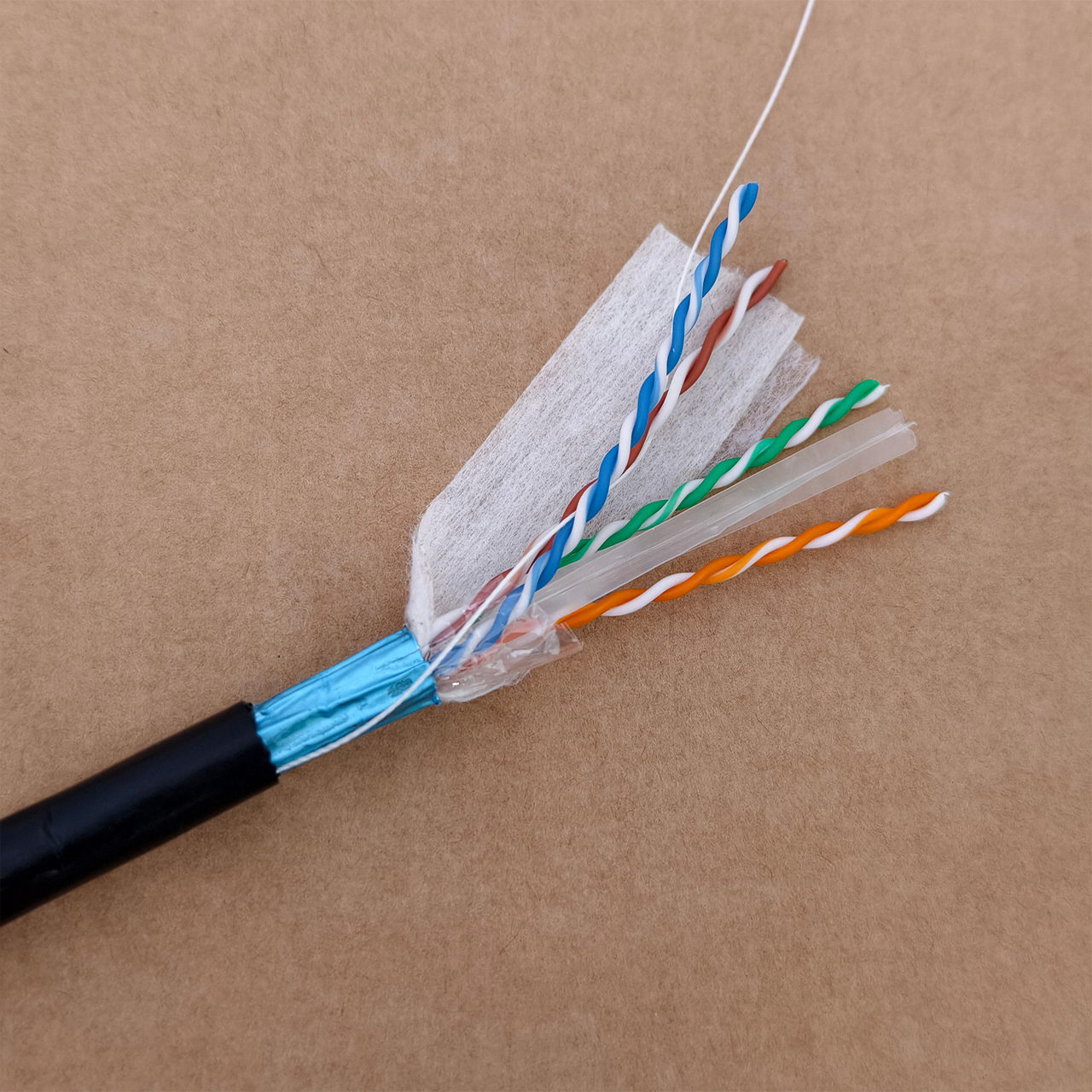

CCAM wire manufacturing involves coating an aluminum core with a thin copper layer and adding magnesium to improve strength and flexibility. Key stages include wire drawing, coating, annealing, and quality checks for conductivity and corrosion resistance. This composite process results in a cost-effective, lightweight, and conductive material ideal for industrial applications, balancing performance with economic efficiency, thus promoting widespread adoption in the telecommunications industry.

Product Application Scenarios

CCAM wire CAT7 LAN cables are extensively used in network installations requiring high-speed data transmission, such as data centers and cloud computing environments. Their lightweight nature and cost-efficiency make them perfect for large-scale implementations. Furthermore, their excellent shielding capabilities reduce noise and interference in densely packed electronic setups, promoting robust signal integrity even in challenging conditions.

Product After-sales Service

- Comprehensive technical support available.

- One-year warranty for manufacturing defects.

- Prompt response to customer inquiries within 24 hours.

- Replacement policy for defective items.

Product Transportation

- Shipped from Ningbo port.

- Standard export packaging ensures safe transit.

- Tracked delivery service available upon request.

Product Advantages

- Cost-effective solution with CCAM wire.

- High-speed data transfer capability.

- Lightweight for easy handling and installation.

- Corrosion resistance extends lifespan.

- Versatile applications in telecommunications and electronics.

Product FAQ

- What is CCAM wire? CCAM wire is a composite conductor made of an aluminum core clad with copper and reinforced with magnesium, offering a balance of cost-effectiveness and performance.

- Where can CCAM wire be used? It is widely used in telecommunications, automotive, and consumer electronics for applications requiring lightweight and cost-effective conductivity solutions.

- Does the cable support PoE? Yes, this CAT7 cable supports Power over Ethernet (PoE) applications.

- What are the MOQ terms? Minimum order quantity is 100 rolls, a standard for wholesale purchases.

- Is the product environmentally compliant? Our products meet RoHS regulations, ensuring limited environmental impact.

- Can the cable withstand outdoor use? While primarily designed for indoor use, the jacket options provide moderate protection for some outdoor applications.

- What is the advantage of using CCAM wire? CCAM wire combines the strengths of aluminum, copper, and magnesium, providing lightweight, corrosion-resistant, and cost-effective solutions.

- Is customization available? Yes, we offer logo and color customization for bulk orders.

- What is the product's delivery time? Delivery times depend on order size but typically range from 2-4 weeks.

- Do the cables comply with any standards? Yes, they conform to IEC, EIA-TIA performance requirements, ensuring quality and compatibility.

Product Hot Topics

- Why choose CCAM wire for high-speed applications? The combination of aluminum's light weight and copper's excellent conductivity makes CCAM wire an ideal choice for high-speed applications, balancing cost and performance for robust network solutions.

- CCAM wire: Revolutionizing the cabling industry CCAM wire introduces a cost-conscious alternative to traditional copper cables without sacrificing significant performance, making it a game-changer for large-scale cabling projects.

- How does CCAM wire ensure signal integrity? By integrating superior shielding and flexibility, CCAM wire effectively minimizes interference and maintains high signal integrity, even in complex electronic environments.

- Meeting modern data demands with CCAM wire As data centers push for higher bandwidth, CCAM wire provides the necessary infrastructure to meet these demands with its 10Gbps data rate capability.

- Exploring the economics of CCAM wire Utilizing CCAM wire allows telecommunications companies to reduce costs significantly while maintaining reliability and efficiency in their networks.

- CCAM wire's role in sustainable technology With its reduced material cost and environmental compliance, CCAM wire supports sustainable practices in the technology sector.

- Adapting CCAM wire to future technologies As technology evolves, CCAM wire's flexible design ensures it remains compatible with emerging data transmission standards.

- CCAM Wire vs. Traditional Copper Cables While traditional copper offers superior conductivity, CCAM wire provides sufficient performance at a lower cost, making it more accessible for various applications.

- The science behind CCAM wire's durability The combination of copper cladding and aluminum core ensures that CCAM wire withstands environmental stresses while maintaining operational efficiency over time.

- CCAM wire's growth in telecommunications With increasing demand for faster and more reliable networks, CCAM wire's role in telecommunications continues to expand, supported by its versatile performance characteristics.

Image Description