Product Main Parameters

| Parameter | Specification |

|---|---|

| Conductor | Class 5 flexible annealed plain copper |

| Insulation | PVC or LSZH |

| Nominal Voltage | 300 / 500 V |

| Temperature Range | -5°C to 70°C (flexible use) |

Common Product Specifications

| Description | Number of Cores | Outdoor Diameter (mm) | Weight (kg/km) |

|---|---|---|---|

| CY 3 core, 0.5mm | 3G0.5 | 6.1 | 59 |

| CY 4 core, 0.5mm | 4G0.5 | 6.5 | 71 |

| CY 5 core, 0.5mm | 5G0.5 | 7.0 | 86 |

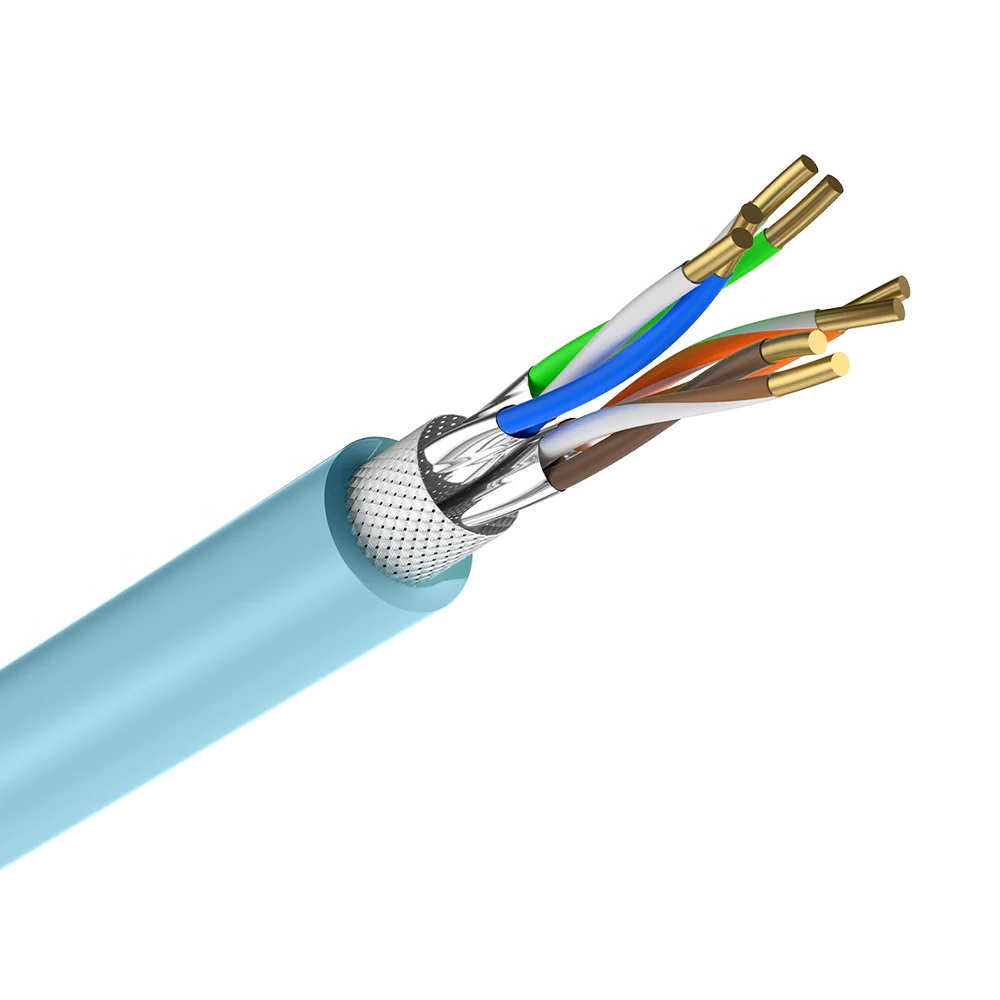

Product Manufacturing Process

The manufacturing process of CY access control cables involves a series of precise steps to ensure optimal performance and reliability. Initially, high-quality copper is drawn into fine strands to form the conductor. The strands are then annealed for flexibility. This is followed by insulating the conductor with either PVC or LSZH materials, which provide necessary electrical insulation and environmental protection. The cables are then braided with tinned copper for enhanced shielding against electromagnetic interference. Finally, an outer sheath, typically of PVC, is applied for additional protection. Throughout production, stringent quality control checks are implemented to guarantee product compliance with international standards and specifications. According to recent studies, such manufacturing processes are integral for producing cables that meet the demands of modern security and data infrastructure, combining durability with excellent conductive properties.

Product Application Scenarios

CY access control cables are versatile and can be deployed in various scenarios that demand reliable communication and control. These cables are ideal for use in industrial settings where machinery must be precisely controlled and monitored. In office environments, CY cables effectively integrate with data processing systems, ensuring smooth operations. Additionally, their application extends to automated production lines, where they serve as interconnecting cables between different control elements. Given the growing importance of security systems, CY cables are prominently used in access control settings, facilitating communication between card readers, door locks, and control panels. Recent studies emphasize the suitability of CY cables in environments requiring robust shielding against electromagnetic interference, ensuring data integrity and operational reliability.

Product After-sales Service

Our commitment to customer satisfaction extends beyond the sale with dedicated after-sales support. We offer comprehensive guidance on installation and maintenance to ensure optimal performance of your CY access control cables. Our technical support team is available to address any queries or concerns promptly, providing solutions tailored to your specific needs. In case of any defects or issues, our warranty policy covers repair or replacement, ensuring peace of mind. We also provide detailed documentation and user manuals to assist with troubleshooting and maximizing the lifespan of your cables. Our goal is to ensure you have a seamless experience from purchase through the duration of product use.

Product Transportation

The transportation of wholesale CY access control cable types is handled with the utmost care to preserve product integrity. Our packaging is designed to withstand the rigors of transit, protecting the cables from mechanical impact and environmental factors. We collaborate with reliable logistics partners to ensure timely and secure delivery to your specified location. Detailed tracking information is provided, allowing you to monitor the progress of your shipment. Our logistics team is readily available to coordinate special shipping requirements or address any transportation-related inquiries, ensuring a smooth delivery process.

Product Advantages

- Flexibility: Offers both fixed and flexible installation options suitable for varied applications.

- EMI Shielding: Enhanced shielding with tinned copper braid reduces electromagnetic interference.

- Durability: High-quality materials ensure longevity even under medium mechanical stress.

- Compliance: Meets international standards including ISO9001, CE, and RoHS.

- Versatility: Suitable for diverse environments including dry, damp, and wet conditions.

Product FAQ

- What are the minimum order quantities for wholesale? The MOQ for our CY access control cable types is 30KM, ensuring you receive the best value for bulk purchases.

- Can the cables be used outdoors? CY cables can be installed outdoors provided they have UV protection and are placed within the recommended temperature range.

- Are these cables suitable for PoE applications? Yes, the twisted pair configurations used in CY cables can support Power over Ethernet applications, especially in reduced EMI environments.

- How do I ensure the longevity of these cables? Regular inspections and adherence to installation guidelines will help maintain cable integrity and prolong their lifespan.

- What's the primary use of CY access control cables? These cables are primarily used in security systems for controlling and connecting various components efficiently and reliably.

- Are these cables resistant to chemicals? Yes, CY cables offer resistance to certain acids, caustic solutions, and oils, making them suitable for industrial applications.

- What certifications do these cables possess? Our CY cables are compliant with ISO9001, CE, IEC, and RoHS standards, ensuring quality and safety.

- What's the typical delivery time frame? Delivery timeframes can vary; however, we aim to process and ship your order as quickly as possible, providing you with tracking details.

- Can I customize the cables? We offer OEM services, allowing you to customize your order to meet specific branding or functional requirements.

- How is cable performance affected by temperature? CY cables perform optimally within the specified temperature range, with extreme temperatures potentially affecting flexibility and durability.

Product Hot Topics

- Discussion on the Benefits of Bulk Purchasing CY Access Control Cable Types: Purchasing CY access control cable types in wholesale offers significant cost savings, especially for large-scale installations where extensive cabling is needed. It also ensures the consistency of supply, reducing the risk of running out of stock during critical projects. Regular users have noted the convenience of having a centralized order which covers multiple installations, streamlining inventory management and logistics.

- The Role of CY Access Control Cable Types in Modern Security Systems: As security systems evolve, the demand for reliable and versatile cabling options grows. CY access control cables play a pivotal role in maintaining the integrity of communication between various security components. Their flexibility and robust shielding capabilities have been highlighted in recent industry reports as key factors contributing to enhanced system reliability and data protection.

Image Description