Product Main Parameters

| Parameter | Specification |

|---|---|

| Impedance | 75 Ohms |

| Conductor Material | 100% Copper |

| Shielding | 95% Braid Coverage |

| Jacket Material | PVC/PE |

| Conductor Diameter | 1.02mm |

Common Product Specifications

| Attribute | Details |

|---|---|

| Length | Customized |

| Color | Customized |

| Connector Compatibility | BNC |

| Weight | 6.0KG/100m |

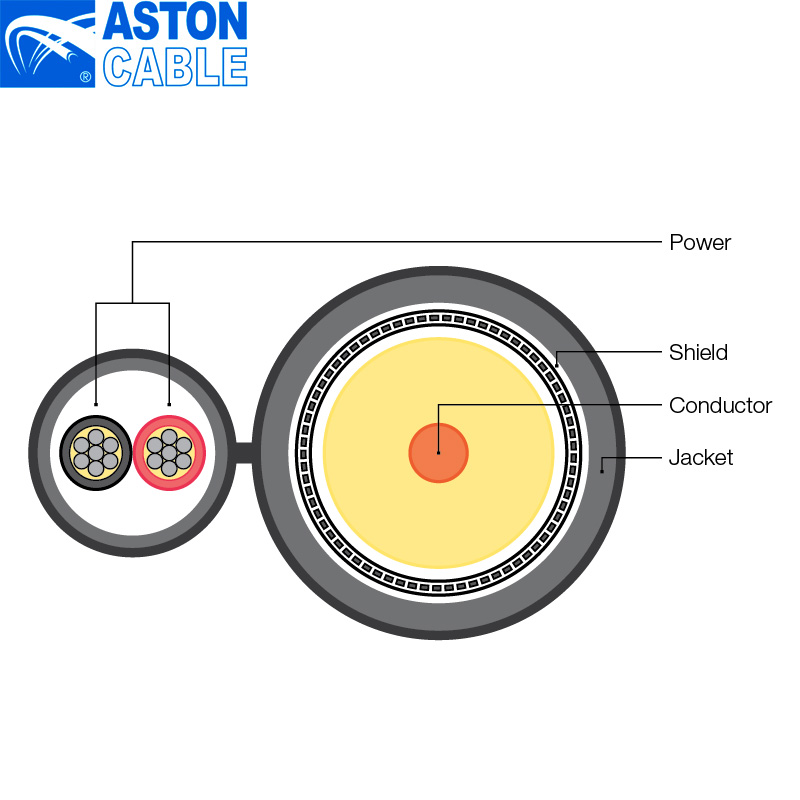

Product Manufacturing Process

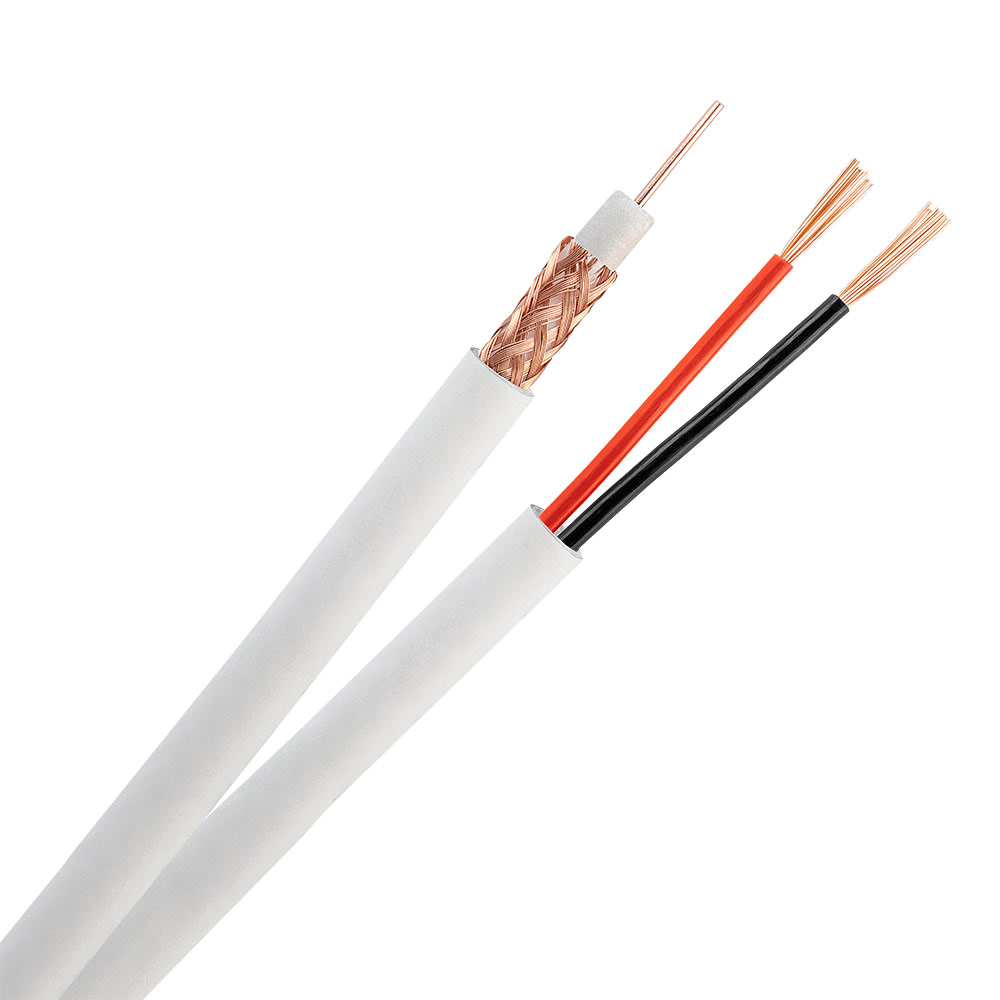

RG11 75-ohm coaxial cable manufacturing involves several key steps to ensure quality and performance. The process begins with selecting high-grade copper or copper-clad steel for the inner conductor. This is followed by applying a dielectric insulator, typically made from polyethylene, to maintain impedance. Next, multi-layer shielding, consisting of aluminum foil and braided copper, is added to protect against interference. Finally, a durable outer jacket of PVC or PE is extruded to shield the cable from environmental factors. Each stage of the process entails rigorous testing to comply with industry standards for reliable communication over long distances. This comprehensive process ensures the RG11 cable's low attenuation and high frequency support.

Product Application Scenarios

RG11 75-ohm coaxial cables are vital in applications where high-quality signal transmission is necessary. In cable television setups, the cable's low attenuation allows for efficient distribution of signals over long distances. It's also employed in satellite communications to minimize signal loss from outdoor dishes to indoor equipment. In the internet infrastructure sector, RG11 cables facilitate high-speed data connections in broadband networks. Their robust construction makes them suitable for both residential and commercial installations, ensuring stable performance even in harsh environments. The cable's ability to support high-frequency signals also suits modern telecommunications and broadcasting needs.

Product After-Sales Service

- Offer a 1-year warranty on all RG11 coaxial cables.

- Provide online technical support for installation and troubleshooting.

- Return and exchange policy within 30 days of delivery.

- Dedicated customer service team for prompt assistance.

Product Transportation

- Standard packaging for weather resistance during transport.

- Available in coil reel, plastic drum, or wooden drum packaging.

- Shipped via secure logistics partners to ensure timely delivery.

Product Advantages

- Low signal attenuation over long distances.

- High-frequency support suitable for modern communication needs.

- Durable construction for long-term reliability.

Product FAQ

- Q1: What is the impedance of the RG11 coaxial cable?

A1: The RG11 coaxial cable has an impedance of 75 ohms, which is optimal for minimizing signal reflection. - Q2: Can I use RG11 cables for outdoor installations?

A2: Yes, RG11 cables with PE jackets are suitable for outdoor use, offering protection against environmental elements. - Q3: What are the main applications for RG11 coaxial cables?

A3: RG11 cables are primarily used in cable TV, satellite communication, and broadband internet systems for their superior transmission capabilities. - Q4: How does RG11 compare to RG6?

A4: While RG11 is thicker and offers lower signal loss over long distances, it is less flexible and more expensive compared to RG6 cables. - Q5: Is it possible to customize the color of the RG11 cable?

A5: Yes, we offer customization in color to meet specific project requirements. - Q6: Are the cables RoHS compliant?

A6: Yes, our RG11 coaxial cables are RoHS compliant, ensuring they meet environmental and safety standards. - Q7: What is the minimum order quantity for wholesale?

A7: The minimum order quantity for wholesale RG11 coaxial cables is 30 KM. - Q8: Can RG11 cables handle 4K video signals?

A8: Yes, RG11 cables support high-frequency signals suitable for 4K video transmission requirements. - Q9: What type of connectors are compatible with these cables?

A9: RG11 cables are compatible with standard BNC connectors used in many telecommunications applications. - Q10: How do you ensure product quality?

A10: Each batch of RG11 cables undergoes stringent testing for electrical and physical properties to meet industry standards.

Product Hot Topics

- Topic 1: The Importance of Impedance Matching in RG11 Coaxial Cables

RG11 coaxial cables are designed with a specific impedance of 75 ohms, which is critical for ensuring minimal signal reflection and optimal performance in communication systems. Impedance matching between the cable and connected equipment is crucial to maintaining signal integrity, especially over long distances where even minor mismatches can lead to significant signal loss. Understanding impedance matching can help in choosing the right cable for specific applications and configurations, whether in TV broadcasting or internet infrastructure. - Topic 2: Comparing RG11 and RG6: Which Cable is Right for You?

When it comes to selecting coaxial cables, RG11 and RG6 are two popular choices, each with distinct advantages depending on the application. RG11 cables, offering lower signal attenuation, are ideal for long-distance runs but come at a higher cost and are less flexible than RG6. On the other hand, RG6, being more flexible and economical, suits shorter runs and installations with space constraints. Understanding the key differences can aid in making an informed decision for both residential and commercial projects. - Topic 3: Environmental Considerations for RG11 Coaxial Cable Installation

Installing RG11 coaxial cables in outdoor environments requires careful consideration of environmental factors such as UV exposure, temperature fluctuations, and moisture. Cables with PE or UV-resistant PVC jackets can offer additional protection against weathering, extending the service life of the installation. Proper installation techniques, such as minimizing sharp bends and avoiding direct burial without protective conduits, can further enhance durability and performance in varied climatic conditions. - Topic 4: Ensuring High-Frequency Performance in Telecommunications

The ability of RG11 coaxial cables to handle high-frequency signals makes them an excellent choice for modern telecommunications and broadcasting applications. With the growing demand for high-speed internet and 4K video transmission, RG11's robust construction minimizes signal deterioration, even at higher frequencies. This makes it a preferred option for installations requiring reliable data and video signal delivery, ensuring optimal user experiences. - Topic 5: The Role of Shielding in Enhancing Cable Performance

Shielding plays a pivotal role in maintaining the integrity of signals transmitted through RG11 coaxial cables. By reducing electromagnetic interference, shielding ensures that external noise does not impact the signal carried within the cable. The multiple layers of braided copper and aluminum foil in RG11 offer superior protection, making these cables suitable for environments with significant RF and EMI concerns. Understanding the role of shielding can aid in selecting the right cable for challenging electromagnetic environments. - Topic 6: A Guide to Selecting the Right Jacket Material for Coaxial Cables

Choosing the right jacket material for RG11 coaxial cables depends on the intended installation environment. PVC jackets are commonly used for indoor applications, offering flexibility and ease of installation. For outdoor or industrial settings, PE or LSZH (Low Smoke Zero Halogen) materials provide better resistance to environmental factors like UV light and moisture. Each material has its advantages, and the choice should be guided by specific use case scenarios and safety standards. - Topic 7: Cost vs. Performance: Navigating Coaxial Cable Purchases

When purchasing RG11 coaxial cables, weighing cost against performance is essential for maximizing value. While RG11 offers superior performance for long-distance transmission, the increased cost can be a factor in budget-conscious projects. However, investing in high-quality cables can prevent future issues related to signal degradation and interference, ultimately saving costs on maintenance and replacements. Evaluating both immediate needs and long-term benefits is crucial for strategic decision-making. - Topic 8: The Importance of Quality Assurance in Cable Manufacturing

Quality assurance in the manufacturing of RG11 coaxial cables ensures that each cable meets stringent industry standards for performance and reliability. At Aston Cable, rigorous testing is conducted at every stage of production, from raw material selection to final product inspection, to ensure each batch adheres to specifications. This commitment to quality guarantees that customers receive dependable products ready for high-demand applications. - Topic 9: Exploring the Evolution of Coaxial Cables in Telecommunications

Coaxial cables have evolved significantly since their initial use in telecommunications, adapting to the increasing demands for data capacity and signal quality. Developments in materials, shielding techniques, and manufacturing processes have enhanced the capabilities of RG11 cables, making them indispensable in current high-speed internet and broadcast applications. Understanding this evolution provides insight into future trends and technological advancements in cable design. - Topic 10: Sustainable Practices in Coaxial Cable Manufacturing

Adopting sustainable practices in the production of RG11 coaxial cables is crucial for reducing environmental impact. By incorporating recycled materials, minimizing waste, and optimizing energy use during manufacturing, companies like Aston Cable contribute to eco-friendly initiatives. By choosing products from environmentally conscious manufacturers, consumers can support sustainability goals while maintaining high-quality communication solutions.

Image Description