Product Main Parameters

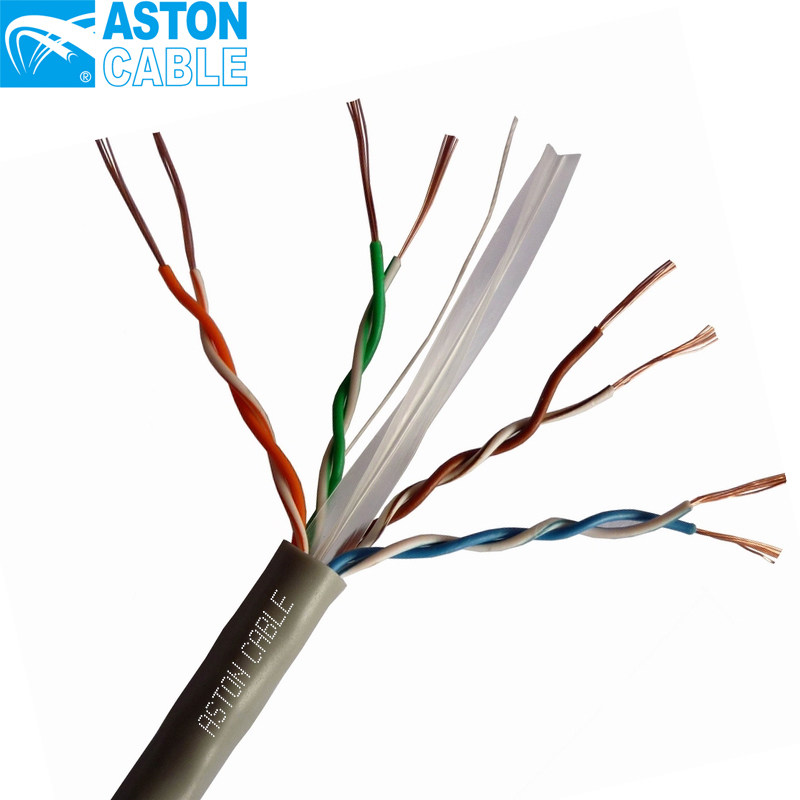

| Conductor | 1.02MM 18AWG |

| Insulation | Gas Injected Polyethylene |

| Jacket Material | PVC |

| Color | White, Black, Customized |

| Cable Diameter | 0.265'' Nominal |

| Shield | 100% Al Foil 61% CCA. Braid (36 AWG) |

Common Product Specifications

| Nominal Cable Weight | 35 lbs/1000 ft |

| Attenuation | 5 MHz - 5 MHz - 1.7 dB/100m, 1000 MHz - 19.8 dB/100m |

| Daily Output | 200KM |

| MOQ | 30km |

| Supply Ability | 25000KM/Per year |

Product Manufacturing Process

The manufacturing process of coaxial cables involves several detailed stages to ensure high-quality standards. Initially, materials are selected based on electric and mechanical requirements. The conductor is first coated in dielectric insulation, then shielded with foil and braid layers to prevent electromagnetic interference. The outer jacket is applied to protect the internal components. According to authoritative papers, this combined layer design provides better signal integrity and reduced attenuation, especially crucial in telecommunications.

Product Application Scenarios

Coaxial cables, particularly RG6, are predominantly used in applications requiring minimal signal loss and strong electromagnetic shielding. Telecom industries use these cables extensively in CATV networks and satellite transmissions. According to recent studies, RG6 cables outperform other variants in dense urban settings due to their superior ability to maintain signal quality over longer distances, making them a preferred choice in high-frequency applications.

Product After-Sales Service

We offer a comprehensive after-sales service including warranty coverage, technical support, and replacement of defective products. Our team is dedicated to ensuring customer satisfaction by addressing any issues promptly. For wholesale orders, special service agreements are available.

Product Transportation

All products are packed in robust export packaging to withstand transit conditions. We partner with reliable carriers to ensure timely delivery worldwide, leveraging our proximity to Ningbo port for efficient logistics.

Product Advantages

- High signal integrity with pure copper option.

- Cost-effective CCA provides a budget-friendly alternative.

- Extensive durability and flexibility for various environments.

Product FAQ

- Q: What are the benefits of using CCA wires?

A: CCA wires offer a cost-effective alternative to copper, reducing production costs due to the cheaper and lighter aluminum core. This choice provides a budget-friendly solution for projects where cost is a priority. - Q: How do CCA and copper wires differ in performance?

A: Copper wires have superior conductivity, ensuring minimal signal loss. CCA wires, while cost-effective, tend to have higher resistance and are better suited for non-critical applications. - Q: Are CCA wires suitable for outdoor use?

A: CCA's aluminum core is more prone to corrosion, which could be a concern. However, the copper cladding may offer adequate protection in less aggressive environments. - Q: Can these cables be customized?

A: Yes, we offer customization options for jacket colors and conductor specifications to meet specific project requirements. Contact us for more details. - Q: What is the minimum order for wholesale purchases?

A: Our MOQ for wholesale orders is 30km. This allows us to maintain efficient manufacturing and competitive pricing. - Q: How does the cable's weight impact installation?

A: Lighter cables such as CCA are easier to install in situations where weight is a factor, such as overhead cabling or in reduced support structures. - Q: What are the shipping options?

A: We provide several shipping options catered to your needs, including express and sea freight, leveraging our proximity to Ningbo port for fast delivery. - Q: Are there any environmental considerations for these cables?

A: Our products are RoHS-compliant, ensuring they meet stringent environmental standards for safety and sustainability. - Q: What kind of packaging is used for shipping?

A: We use durable export packaging to protect our cables during transit, ensuring they arrive at your location in optimal condition. - Q: Do your cables support high-frequency applications?

A: Yes, particularly our pure copper cables are designed for high-frequency scenarios where signal integrity is paramount, such as data transmission networks.

Product Hot Topics

- Comparison: CCA vs Copper Wire in High-frequency Applications

Many debate whether CCA can truly compete with pure copper in high-frequency applications commonly found in telecom industries. While copper retains superior conductivity, CCA provides a viable budget-friendly alternative when extreme performance isn't critical. - Environmental Impact of CCA vs Copper Wire

The environmental considerations of using CCA vs copper wire are important, especially with global shifts towards sustainability. CCA offers a material-efficient choice with lower initial costs, but copper's durability and recyclability often sway long-term environmental strategies. - Durability and Longevity: CCA vs Copper Wire

In harsh environments, choosing between CCA and copper can impact cable lifespan significantly. Copper wires, with their high corrosion resistance, naturally outperform CCA in durability, especially in chemically aggressive settings. - Installation Challenges of CCA vs Copper Wire

Installers face unique challenges when working with CCA vs copper wire, ranging from flexibility to weight and handling costs. Proper training and understanding of each material's properties can optimize installation efficiency. - Cost Analysis: CCA vs Copper Wire

For projects heavily dependent on budget constraints, CCA provides a remarkable advantage. However, when calculating total lifecycle costs, including maintenance and potential signal losses, copper might still offer better value in high-performance applications. - Signal Integrity: CCA vs Copper Wire

Signal integrity remains a decisive factor when comparing these two wiring alternatives. While both strive to reduce attenuation, copper inherently offers superior performance, crucial in data-sensitive networks. - Weight Considerations in CCA vs Copper Wire Applications

Weight is a key factor in aerospace and automotive industries, where CCA's lighter structure could lead to enhanced vehicle efficiency, influencing the decision to select CCA over copper despite performance trade-offs. - Market Trends: Wholesale Demand for CCA vs Copper Wire

The wholesale market for CCA vs copper wire is often influenced by macroeconomic factors and technological advancements. Understanding these trends assists in forecasting demand and making informed bulk purchase decisions. - Technological Advances in CCA vs Copper Wire

Innovations in material science may soon challenge the existing paradigms of wire selection. Emerging techniques that enhance CCA's conductivity could redefine its role in industries traditionally dominated by copper. - Industry Applications: CCA vs Copper Wire

Across industries, the choice of CCA vs copper wire aligns with specific requirements. In areas like residential wiring, where high conductivity isn't paramount, CCA prevails, whereas copper's supremacy remains uncontested in critical telecom infrastructures.

Image Description