Product Main Parameters

| Parameter | Details |

|---|---|

| Conductor | Bare Copper |

| Insulation | PVC |

| Screening | Braided Steel Wire |

| Outer Sheath | Transparent PVC |

| Length | Custom, MOQ 200 Rolls |

| Origin | Hangzhou, China |

Common Product Specifications

| Specification | Details |

|---|---|

| Certification | SGS, CE, RoHS, ISO9001 |

| Daily Output | 200KM |

| Conductor Size | 23AWG |

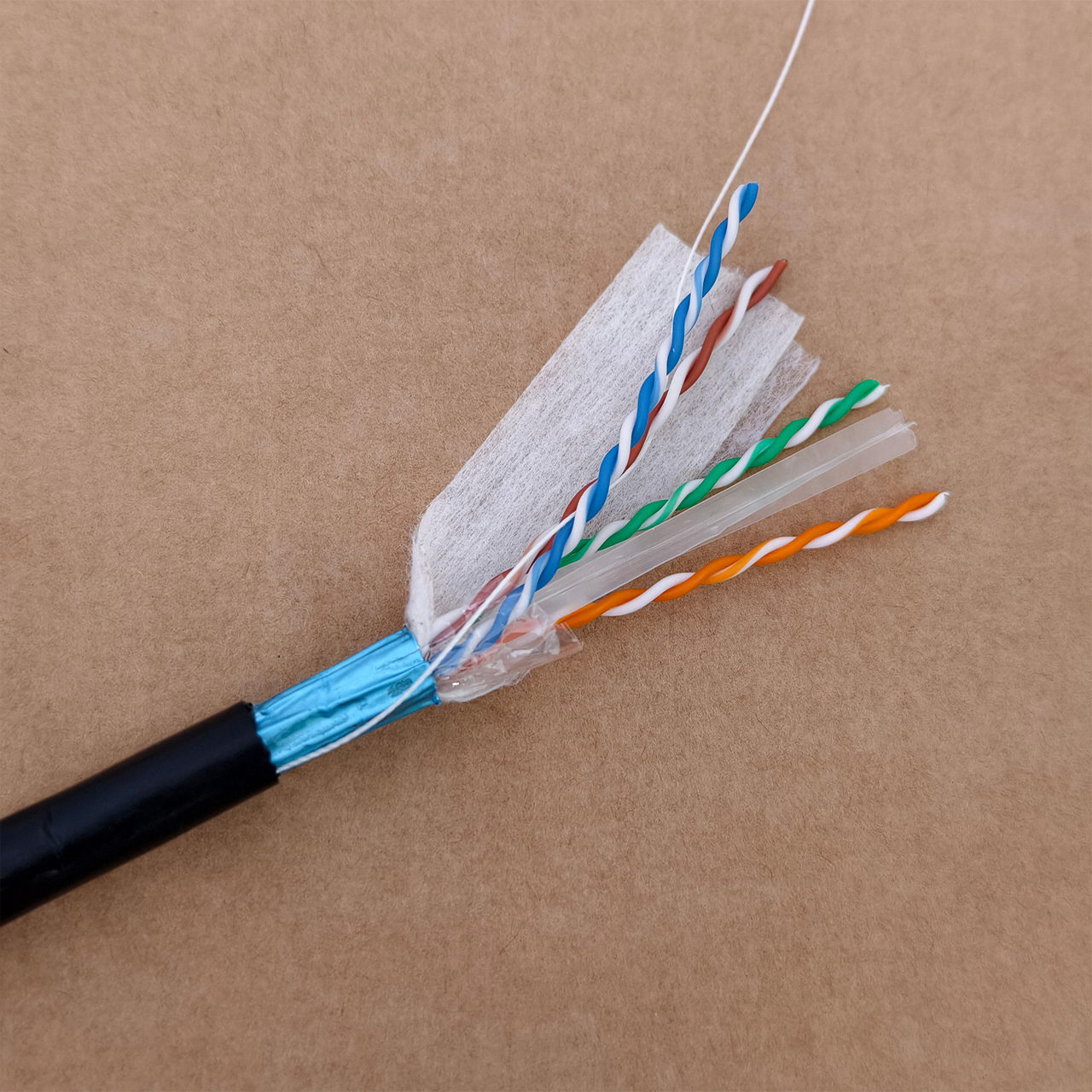

Product Manufacturing Process

SY cable production involves several key steps to ensure high quality and compliance. The process begins with the selection of fine copper strands for the conductor, providing excellent conductivity and flexibility. These strands are coated with a PVC insulation layer, offering electrical safety and thermal resistance. The next step involves applying a braided steel wire for mechanical protection and EMI shielding, crucial for maintaining signal integrity in industrial environments. Finally, a transparent PVC outer sheath is added, allowing for visual inspection of the cable’s condition and providing protection against environmental factors such as moisture and chemicals.

Product Application Scenarios

SY cables are crucial in industrial applications where flexibility, durability, and EMI protection are required. In automation and control, these cables connect control panels to machinery, ensuring reliable operation in dynamic environments. They are also used extensively in instrumentation, where precision and resistance to electrical noise are paramount. Additionally, SY cables are ideal for machine tool wiring and assembly lines, where they are favored for their ability to withstand mechanical stress and repetitive motion. Compliance with standards such as BS7671 is essential for safe and effective integration into these systems.

Product After-Sales Service

We offer comprehensive after-sales support to ensure customer satisfaction. Our service includes technical assistance, troubleshooting, and replacement of defective products under warranty.

Product Transportation

Our products are shipped via reliable logistics partners, ensuring timely and secure delivery. Packaging adheres to international standards to prevent damage during transit.

Product Advantages

- High flexibility for dynamic environments

- Strong EMI protection for stable signals

- Durable and resistant to harsh conditions

- Compliance with BS7671 safety standards

Product FAQ

What is the MOQ for SY Cable?

The minimum order quantity for our SY cable is 200 rolls, customized lengths available.

Is SY cable suitable for outdoor use?

While primarily designed for indoor industrial applications, SY cables can be used outdoors if adequately protected against environmental factors.

What certifications do your SY cables have?

Our SY cables are certified by SGS, CE, RoHS, and ISO9001, ensuring quality and compliance with international standards.

Can I order a custom length for the cable?

Yes, we offer custom lengths for SY cables with a minimum order requirement. Contact us for specific requests.

What type of conductor is used in SY cables?

SY cables use fine, bare copper strands to provide excellent conductivity and flexibility suitable for industrial applications.

How does the steel wire braid benefit SY cables?

The braided steel wire provides mechanical protection and EMI shielding, which is essential in environments with substantial electrical noise.

Are SY cables compliant with BS7671?

While SY cables are not directly referenced in BS7671, they are manufactured to meet the standard's safety and suitability principles.

What industries commonly use SY cables?

Industries such as automation, instrumentation, and manufacturing commonly use SY cables due to their robustness and flexibility.

Can SY cables be buried directly?

Direct burial is not recommended without additional protection as these cables are not designed for sustained exposure to soil conditions.

What installation precautions should be taken with SY cables?

Ensure the cable is suitable for the environment, protected against overloads, and correctly incorporated into earthing and bonding systems.

Product Hot Topics

How does SY cable's EMI protection benefit industrial automation?

Electromagnetic interference can severely impact the performance of industrial automation systems, causing data corruption and equipment malfunction. SY cables incorporate braided steel wire screening, providing robust EMI protection. This shielding is crucial in maintaining signal integrity and ensuring reliable communication between control panels and machinery. By minimizing EMI, SY cables help prevent disruptions in automated processes, contributing to high efficiency and reduced downtime.

Why choose wholesale SY cables for large projects?

Wholesale purchasing of SY cables is advantageous for large-scale projects. It ensures consistent quality across all installations, which is critical for maintaining system reliability. Additionally, buying in bulk often reduces costs, providing significant savings for businesses. With Aston Cable's expertise and compliance with BS7671, you can be confident in the safety and performance of your SY cables, making them a smart choice for extensive industrial installations.

Challenges in integrating SY cables with existing systems

When integrating SY cables into existing systems, compatibility and compliance with safety regulations like BS7671 are primary concerns. Potential differences in cable specifications require thorough assessment to ensure seamless operation. Moreover, understanding the environmental conditions and mechanical stresses the cables will endure is vital for choosing the appropriate cable type. Collaboration with manufacturers can address these challenges, providing tailored solutions for successful integration.

The role of SY cables in improving machinery efficiency

SY cables play a crucial role in enhancing machinery efficiency by providing reliable connections with optimal signal integrity. Their flexibility allows for easy installation in tight spaces, while the durability ensures long-term performance even in harsh conditions. The EMI shielding is especially beneficial, reducing interference that could otherwise lead to inefficiencies or equipment failure. Overall, SY cables contribute significantly to maintaining and improving operational efficiency in industrial settings.

Environmental considerations when choosing SY cables

Selecting the right SY cable involves considering environmental factors such as temperature, moisture, chemicals, and mechanical abrasion. Cables must be suitable for their specific operating conditions to ensure longevity and performance. For outdoor or chemically challenging environments, additional protective measures or specific cable types may be required. Understanding the installation environment is crucial for making informed decisions and ensuring compliance with safety standards like BS7671.

SY cable maintenance and inspection tips

Regular maintenance and inspection of SY cables are essential for prolonged service life and reliability. Visual inspections of the transparent PVC sheath can quickly identify damage or wear, allowing for timely intervention. Ensuring the cables are free from excessive tension or bending beyond specified limits is crucial. Scheduled maintenance checks, including testing for continuity and insulation resistance, can prevent unexpected failures and ensure compliance with relevant safety standards.

Impact of SY cable compliance with BS7671 on safety

Compliance with BS7671 enhances safety in electrical installations using SY cables. This standard provides guidelines to ensure cables are suitable for their environment and capable of handling the electrical load safely. Adhering to these guidelines minimizes the risk of electrical hazards, such as fires or equipment malfunctions, thus protecting both personnel and infrastructure. Manufacturers like Aston Cable ensure their products consistently meet or exceed these safety benchmarks.

Innovations in SY cable design for enhanced performance

Recent innovations in SY cable design focus on enhancing performance characteristics such as flexibility, EMI protection, and environmental resistance. Advanced materials and manufacturing techniques have led to cables that can perform reliably in even more demanding conditions. These improvements extend the application range of SY cables, offering solutions for industries that require high levels of durability and efficiency while maintaining compliance with standards like BS7671.

The economic impact of deploying SY cables in industry

Deploying SY cables can have a significant economic impact on industrial operations. Their durability and reliability reduce maintenance costs and downtime, while their EMI protection ensures efficient and uninterrupted operations. Investing in high-quality SY cables can lead to notable long-term savings and increased productivity. Moreover, compliance with BS7671 assures businesses that their installations are safe and up to standard, potentially reducing liability and insurance costs.

Customizing SY cable solutions for industry-specific needs

Industries often have unique requirements that standard SY cables may not fully address. Customizing cable solutions involves tailoring specifications such as conductor size, insulation materials, and shielding to meet specific environmental and operational needs. Working closely with manufacturers like Aston Cable allows businesses to develop cables that perfectly align with their technical and regulatory demands, resulting in optimized performance and compliance with standards like BS7671.

Image Description